Isto é um autêntico self-service da CNC!

Partindo desta máquina, podem criar uma Máquina CNC À MEDIDA!

O que quer dizer, uma Impressora 3D, Fresa 3D, Sensor, e o que mais queiram.

E não só isso, mas PODEM FAZER A MÀQUINA À MEDIDA, desde este tamanho gigante, à medida exacta da vossa Bancada de Trabalho.

Maravilha.

Custom additive manufacturing machine

Francois Giguere

DESCRIPTION:

3-Axis Linear Robot that can be used for inspection, CNC routing, 3D printing and more. The robot features a double-driven synchronous drive on the X axis for optimal smoothness and speed. The Z-axis is equipped with a powerful and precise ball screw driven actuator.

https://www.vention.io/designs/6747

Já a HP pensa numa Impressora 3D a cores.

Mas não a ESTE preço, 399 dólares!

E não se esqueçam:

4 bobinas, não significa só 4 cores, mas também 4 tipos diferentes de Filamento, que se podem fundir.

I'd add to the great Article below...

It not allows for 4 color printing, but remember, 4 different types of Filament. Yup, Multi-material, and possible material Fusion.

M3D Launches Full-Color Palette 3D Printer “Crane Quad”

Hanna Watkin

M3D, the American 3D printer manufacturer, is launching a new desktop printer called Crane Quad for under $500. It offers more than 50,000 colors with its full-color palette. This is one of three 3D printers in the new Crane series. Touted as a world first, M3D is launching a full-color 3D printer which they also claim brings a “new era of color 3D printing.” The Crane Quad 3D printer is a new desktop machine from US-based manufacturer, M3D. It promises 50,000 colors, a build volume of 214 x 214 x 230mm, and a full-color palette. Therefore, it is a multi-material 3D printer which can also produce multi-colored objects. To make the printer even more desirable, the starting price is $399. The new printer offers a “QuadFusion” 3D print head, enabling it to print and blend four filaments of most colors and material types, so long as they’re 1.75mm. The direct-drive extruder has four motors, three fans, and a 0.35 mm mixing nozzle.

https://all3dp.com/m3d-launches-full-color-palette-3d-printer-crane-quad

A nova Ultimaker, maior, e melhor...

New Ultimaker S5 3D Printer: Ultimaker Goes Bigger and Better

Tyler Koslow

Originally founded in 2011, the Dutch 3D printer manufacturer Ultimaker has solidified itself as a pioneer in the open source 3D printing community. With a highly praised range of professional-grade 3D printers and one of the most popular 3D printing slicers in Cura, there’s no doubt that Ultimaker is one of the most influential players in the desktop 3D printing market.

In 2016, the company released the Ultimaker 3, a groundbreaking dual extrusion 3D printer that many still consider to be the best that money can buy. Today, at the manufacturing tech trade show Hannover Messe 2018, Ultimaker unveiled the new Ultimaker S5 3D printer, a bigger and better version of the beloved Ultimaker 3.

https://all3dp.com/1/ultimaker-s5-3d-printer-review/

Uma boa fonte de frustração, é imprimir um Objecto que supostamente deveria conter àgua...

E ele nem contém AR!

Para evitar isso, sigam o Instructable indicado abaixo:

Weekend Project: How to 3D Print Watertight and Airtight Containers

Tyler Koslow

A new Instructables post from user mikey77 shows how you can adjust your 3D printing slicer settings to make watertight and airtight containers, cups, tanks, and more.

There are tons of useful and unique objects that you can create with your desktop 3D printer, but there are certain factors that prevent makers from properly producing food-safe and watertight items. Generally speaking, the layering of FDM prints lead to micro spaces that allow bacteria to build up, water to leak, and air to seep out.

But a new Instructables post from user mikey77 claims that with just a few tweaks to your 3D printing slicer settings, you can 3D print containers, cups, and tanks that are watertight and airtight. The concept is simple. All you need to do adjust your slicer to prompt over-extrusion of your filament.

https://all3dp.com/weekend-project-how-to-3d-print-watertight-and-airtight-containers/

Imprimir em ABS é um risco, devido ao cheirete que aquilo produz, e porque esse fumo contém uma boa dose de toxinas, que não interessam a ninguém...

Entra em acção este Instructable, mesmo a pensar nisso:

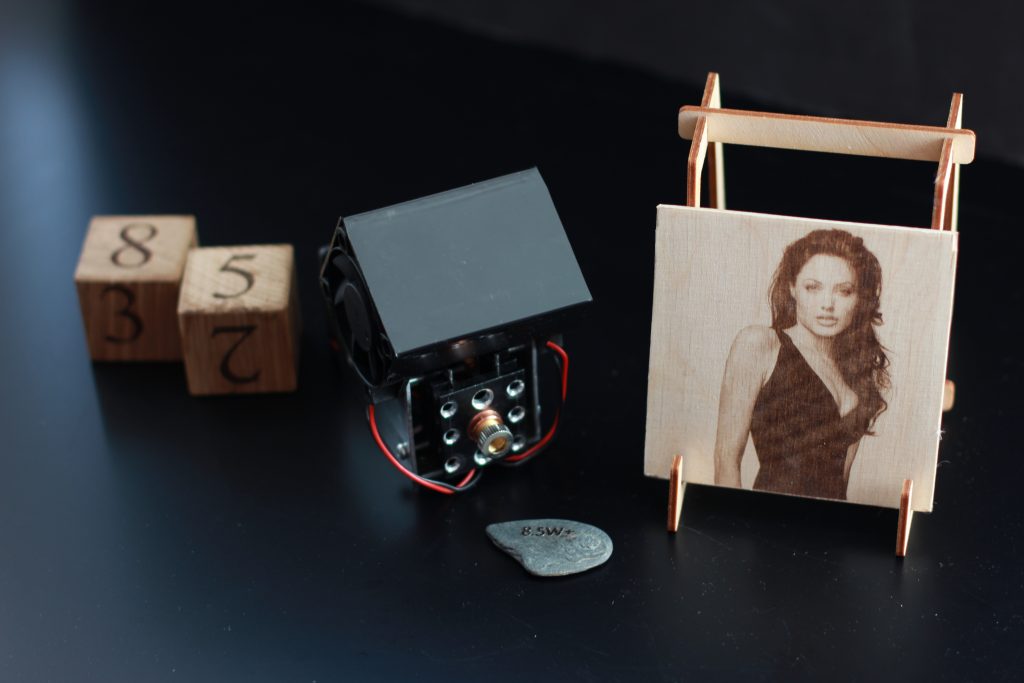

Active Air Filter (HEPA 13 Filter and Active Carbon Pellets)

Deep silence

I initially made this filter to remove the toxic volatile organic compounds and fine particles generated by my 3D printer. It can be, of course, used for other purposes, like filtering the air of a room; just keep in mind it is designed to continuously filter air, not to clean heavy fumes at once.The HEPA filter catches the particules, while the active carbon removes odors.

The box is about 11x11x20 cm big, and contains a HEPA 13 filter and active carbon pellets. The filter is actually a vacuum cleaner filter which seem to be standard, or at least easily findable, and the active carbon pellets can be bought from any aquarium seller, or others.

I mounted a 12V fan, and preferred a silent fan over a powerful one, but you can make different choices. There is a door on the exhaust pipe, used to redirect some of the filtered air back into the printer enclosure (thus keeping a correct temperature inside), which is not mandatory (actually, the exhaust pipe is not mandatory either).

It is difficult to test the filter efficiency without proper tools; at least, the smell inside the printer enclosure is much lighter now that I use this filter...

http://www.instructables.com/id/Active-Air-Filter-HEPA-13-Filter-and-Active-Carbon/