Como me farto de gabar esta minha Velleman Vertex, cá vai o porquê, e como podem verificar no Vídeo, também lá tem umas obas de críticas, não porque me estou a evidenciar, mas porque eles bem que podiam afinar melhor a coisa...

Querem uma Impressora sem Stress, todos os dias?

Tentem esta:

Maybe I'll translate this, one day, but for now, you can try and have it auto-translated, or something;

In a nutshell, it points out the good and the bad, of the Velleman Vertex, why it's ideal for non-geeks, and also shows you how improve it:

It has a slot inside for an USB -Printer Cable, so you can connect it to your PC, beware, room only for the 90 degree jack variety, uses a BuildTak magnetically fixing plate, and I love the thing, faults and all, 'cos it works without dramas and constant re-calibration.

If you connect it to your 'puter, when you cancel a print, be sure to switch the thing off, and remove the USB from the PC, to avoid problems.

Velleman Vertex - O Bom, o Mau, e o Prático

Edgar Castelo

Em chapa de aço, pequena, mas maneirinha, prática...

Mas não acreditem que vem TODA montada. Mas, na análise final, vale a pena.

Este nosso amigo Chinês, um Aficionado da Arte de Imprimir coisas fantásticas, ofereve-vos este culminar da sua Série de Instructables, como imprimir este fantástico Modelo da Lua, para um Candeeiro que é algo de impressionante.

Bravo.

This artful young Chinese Aficionado offers you the chance to make an awesome Moon Lamp, out of your 3D Printer, so just go there, and learn:

High Detailed Moon Lamp

陳亮

Subsequent to my previous instructables, Print Your Own Moon, this instructables show how to model a Moon lamp with finer details.

https://www.instructables.com/id/High-Detailed-Moon-Lamp/

Fazem coisas que querem vender?

Aproveitem esta Dica dos nossos amigos da Ponoko, e aprendam como vender o que fazem, na Etsy:

A Guide To Selling On EtsyDJ HarriganHow Does Etsy Work?

Etsy is a platform for buying and selling handmade goods, supplies, and vintage products. It’s an endless online crafts faire with 1.8 million booths, and millions more customers looking to find just the right thing that you might sell. For some small fees, Etsy hosts your shop and provides powerful tools for you to manage your business, and for potential customers to find what you have to offer. It’s popular platform for good reason, and today I’ll be telling you how to get a piece of that handmade pie.

Ter uma Forja no quintal, é o sonho de tanto Engenhocas, pois aprendam com quem sabe, como fazer tal coisa:

A Propane Forge! MEWAHAHAHA! Need I say more?

Learn how it's done, the proper way.

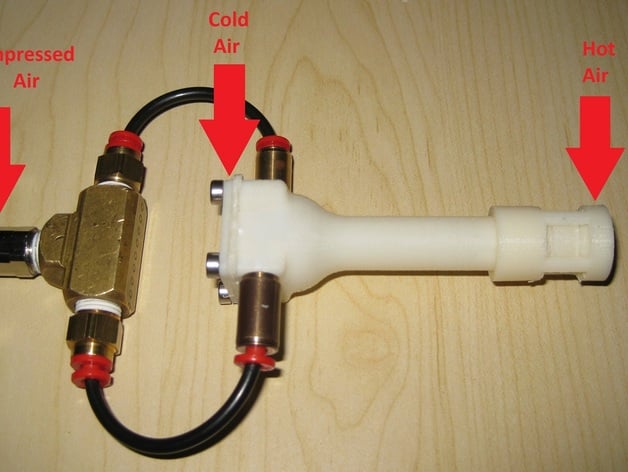

How to Make a Propane ForgeMaxPower1977In this Instructable I show you how to make a high efficiency propane forge. I have made a few forges so I have a good idea how they go together but I will give reference and credit to Ron Reil and his designs, that is where I learned how to build them over 12 years ago.

This forge can be used for knife making, blacksmithing, glass making or anything else you can think of that requires heating up stuff to a really hot temperature.

I have access to a welder so I was able to weld some parts together for this forge but if you don't have access or know how to weld, an option is you can braze the parts together or be creative and bolt things together.

Isto é, ou não é, uma maravilha?

Este Site oferece-vos uma data de coisas boas, desde E-books para Principiantes, e já Versados, a esta Jóia, uma Aplicação Web para calcularem QUANTO $ devem cobrar, sem perderem nem Dinheiro, nem Clientes...

Impecável.

Vão lá!

A Gem I've found, this site offers you a ton-load of good 3D knowledge, Ebooks, a 3D Print Price Calculator, help, you name it.

Now you will know HOW MUCH to ask for, not losinge either Money, nor Clients:

The True Cost of Running a Desktop 3D PrinterJason KingWhenever I show my latest 3D prints to people, the one question they always ask me is “How much did this cost to make?”

My answer is usually along the lines of “I’m not sure and I’m not worried because I’m going to make it anyway”.

This is a good question and my answer is honest and true, but I realised recently that my answer simply isn’t good enough. It’s at around this time that I received a comment on my Beginners Series Page relating to 3D printer running costs. If I may quote part of the comment:

“I am researching printers and their various features and functions and have found plenty of suppliers who don’t seem to have a clue about printing supply costs relating to quantity on a reel or weight or either and offer little assistance. The one thing you don’t mention is how much does it cost you to run your printer and by this I mean electricity used per hour. It is impossible for me as a budding business owner to put a cost on my item if the makers can’t tell me how much power it uses. I have a kilowatt hour meter to test it but don’t have anything to test it on and I refuse to take anything on faith from these folks since they’ve not been overly helpful on all other questions I’ve asked to date.”

To quote part of my reply:

“I’ve never worked out or tried to find out how much the electricity costs are, because I’ve figure that it’s negligible compared the other resources required, time currently being the biggest resource used in 3D printing. But I should, so maybe I’ll write a blog post soon about the true running costs of a 3D printer. I’ve not yet seen such information published and I think people will certainly find it interesting.”

To address this question I started by purchasing some accurate kitchen scales. Based on the weight of an object and the cost of the filament (plastic) per kg it’s easy to work out the material costs.

This was a good start, but I then started to think about other costs like electricity, equipment depreciation, software, repairs, 3D Printer Upgrades, consumables and of course the cost of all those 3D printing failures.

As you can imagine, working out the true cost of running a desktop 3D printer at home could be tricky, but I like a challenge and as far as I know, this common question remains unanswered. Up until now that is.