MUÁHÁHÁHÁ!

Entusiasmente...

Algo para as Impressoras 3D, os ferros de soldar, e sabe-se lá quantas mais maquinetas que já vos queimaram os dedos, para não falar de Pegas de Cozinha pá Patroa!

É bom.

A Super-Material You Can Make In Your Kitchen (Starlite?)NightHawkInLight

In this video I attempt to recreate a lost supermaterial called Starlite. This material could supposedly resist temperatures up to 10,000 degrees Celsius, having undergone testing by NASA and the Atomic Weapons Establishment in the UK. I believe in this video I have come close in function to the original formula for Starlite, but there is still some work to be done. My result works very well, but for a few reasons I may talk about in a future video I do not believe Starlite used PVA glue as it's binder, and I also suspect a different CO2 producer was used instead of baking soda. More experiments are required.

https://www.youtube.com/watch?v=aqR4_UoBIzY

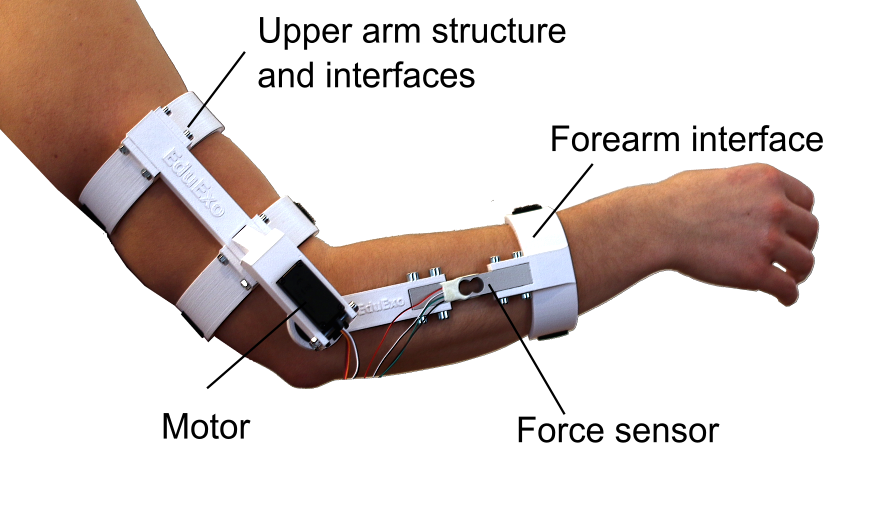

Algo de altamente louvávél, é este Projecto, o EduExo, que vai facilitar bastante a vida a muitos Deficientes Motores, aumentando artificialmente a força de braços debilitados.

Bravo!

EduExo is a DIY exoskeleton kit

Arduino Team

You’ve seen exoskeletons in movies such as Aliens and Iron Man, and perhaps even heard about current experiments with human use. Unfortunately though, if you want to learn about this technology, the barrier to entry is very high.

EduExo, now available on Kickstarter, is an attempt by robotics researcher Volker Bartenbach to bring this technology to the masses. Based on an Arduino Uno, the device takes the form of an upper and lower arm cuff, along with a motor and force sensor to allow it to be used for haptic control.

https://blog.arduino.cc/2017/05/10/eduexo-is-a-diy-exoskeleton-kit/

Quem é que não quer construír isto?

Um Micro-Drone?

Todo o Geek quer um! Pois Jan Olejnik, dos nossos amigos da Prusa, dizem-vos como o fazer, para vosso deleite e edificação...

How to build a cool & cheap 3D printed micro drone

Jan Olejnik

Radio controlled drones are extremely popular and you can get them in all shapes and sizes. In recent years, one specific type of drone has seen a sudden rise in popularity: micro quadcopters. They fit in your palm but can be powered by high-RPM brushless motors and a two-cell Li-Po battery, so they have, potentially, tons of power. Combine it with first-person video transmission and you have one amazing toy that’s nearly indestructible. And today, we’ll demonstrate that RC vehicles and our 3D printers are a perfect match! We’re going to tell you how to build a cheap, yet powerful, 3D printed mini quadcopter suitable for both indoor and outdoor flying thanks to its diagonal size of 90mm (measured from the motor to motor).

https://www.prusaprinters.org/how-to-build-a-3d-printed-micro-drone/

Dos antípodas, que é o mesmo que dizer, do outro lado do Mundo, vem-nos ainda mais esta Dica do sempre bem-disposto nosso amigo da Maker's Muse, para acelerarem nas vossas Impressões 3D, com umas pequenas mudanças aqui e ali...

3D Print parts TWICE as fast with simple slicer tweaks. 3DP101

Maker's Muse

In this video I'll show you how I created a super fast slicer setting "0.3mm Stupid Fast" to create strong prototype parts quickly and reliably on my Prusa MK3 3D Printer. This might be obvious to some, but many 3D Printing enthusiasts never try and push the limit with their print settings. You'll be amazed just how quickly you can churn out parts with a few simple tweaks - in some cases more than twice as fast and just as strong! Just want to see my settings??? Jump to 6:27 ! :)

https://www.youtube.com/watch?v=3kW9SnK4LKc

...E como não quero que vos falte nada, terminamos com este engraçadíssimo Micro-Carro, tele-controlado, e MESMO pequeno!

Até dá para brincar com o Gato, ou assustar as míudas!

LOL

Micro RC CarKRP-01Remote controls cars are now widely available, however there's one astounding model that one can scratch-build. It measures merely 2inches long but is equipped with proportional control system including 12step steering control, headlights and more!