Devido à cada vez maior Censura, muitas vezes descabida, da Facebook, apagarei a página Engenhocas.

E aproveitei para mudar o Link, que era, aparentemente, difícil de decorar.

TOMEM NOTA DESTE NOVO ENDEREÇO,

https://gizmosandstuff.blogspot.pt/

E PASSEM PALAVRA!

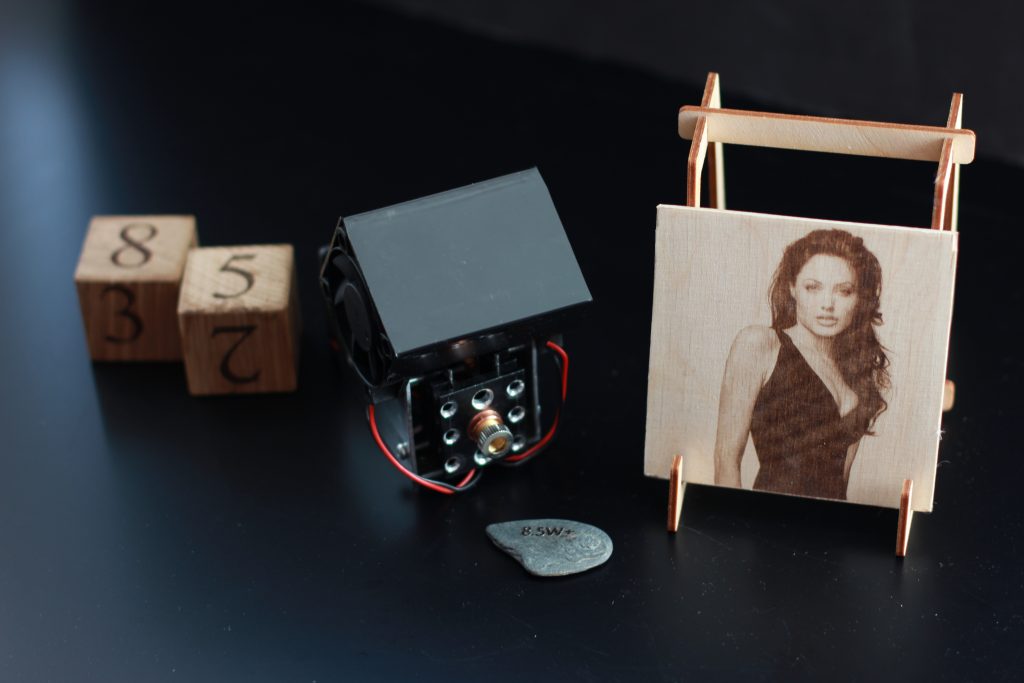

Que tal, terem um Laser na Impressora 3D?

Esta é a proposta da Endurance Lasers, que capacita uma simples Impressora 3D a cortar e gravar, fazendo das vossas máquinas, multi-máquinas!

Vem com um Teste de Calibração do Foco do Laser, e é uma muito boa ideia.

Vejam o Vídeo, abaixo:

Get a discount as Endurance Lasers put metal engraving to the testBeau JacksonEndurance Lasers gives makers the ability to upgrade 3D printers, CNC routers and other DIY machines with multi tool functionality. By installing a laser diode, these machines become cutting tools and engravers, capable of writing on acrylic, wood, leather and metal, maximizing workshop productivity.

The lasers can be installed on any 3D printer or CNC machine to extend capabilities.

Read on for an exclusive discount.The 8.5W+ laser, exclusively available to order from the company’s website, is the second most powerful diode in Endurance Laser’s arsenal. Providing “infinite continuous power,” the 8.5W is capable of writing on all manner of surfaces, from stone and wood to leather and sheet metal.

In a series of Endurance experiments, we see how the 8.5W+ makes short work of matte & hard steel, and glossy & composite aluminum.

https://3dprintingindustry.com/news/get-discount-endurance-lasers-put-metal-engraving-test-131135/

Não hajam dúvidas, a Impressão DLP é o melhor que há, em fidelidade ao Modelo 3D.

Este Modelo, até é melhor que os anteriores, porque em vez dum Laser a andar, usa uma Imagem por camada, e são camadas ínfimas, o que, claro, dá numa fineza de acabamento, de fazer chorar as pedras da calçada... E a menos de 500 Dólares!

Mas, menos de 500 Dólares, também significa um volume máximo de 11,5 x 6,5 x 15,5 Cm, e atenção, há uma cura do Objecto a fazer, e limpezas a executar, porque isto de resinas, é mesmo assim.

Anycubic Photon Review: A DLP 3D Printer For Less Than $500

Anatol Locker

Too good to be true? Not at all! Read our Anycubic Photon DLP 3D printer review and follow us on the journey from unboxing and assembly to the first prints.

As far as low-cost desktop DLP 3D printers go, the new Anycubic Photon DLP 3D Printer has emerged as one of the most appealing options on the market. Anycubic has a reputation for building reliable and affordable printers like the Anycubic i3 Mega FDM 3D printer. When it comes to the price, the Anycubic Photon is no exception – it’s one of the cheapest DLP 3D printers out there.

Don’t miss: 20 Best Resin (SLA/DLP) 3D Printers 2018

We recently got our hands on the Anycubic Photon, and decided to give it a test run. Although this isn’t a full-fledged review, we wanted to document our first experience with this unique 3D printer, as well as the unboxing and assembly process. We will continue to update this review as we get more familiar with this beastly little machine.

The Anycubic Photon DLP 3D printer is generating some serious buzz across the community, and for good reason. Priced right around $450, this machine is a potential game-changer for the SLA/DLP desktop 3D printing sector. But talk is cheap; we wanted to see this 3D printer in action.

https://all3dp.com/1/anycubic-photon-3d-printer-review/

Querem um Espelho para queimar coisas com a luz do Sol?

Muáháháhá!

Mas também pode servir para Telescópios de Reflexão, e o que mais for de Óptica, esta ideia fenomenal, de usar espelhos acessíveis, de Camião, que são convexos, e utilizar A PARTE DETRÁS, removendo a tinta protectora, para obter...

Um espelho Côncavo!

E como nessa parte, não há vidro, a potência de reflexão é ainda maior.

Muito bom.

How To Make Solar Concentrating Mirrors (super HOT focal point)NightHawkInLightIn this video I show how to convert inexpensive truck mirrors into powerful first surface solar concentrators. Check out my sponsor Brilliant for a really fun way to learn! https://www.Brilliant.org/NightHawk First surface mirrors are an extremely efficient way of concentrating solar energy, much more efficient for their size than a fresnel lens. This type of mirror is also essential for optical applications. Check out the video about making first surface mirrors over on GreenPowerScience: https://youtu.be/IaEaaeajCSI

Isto é muito, muito útil!

Objectos 3D que podem ser tão transparentes, que sirvam de LENTES?

As possiblilidades são infinitas.

Como tudo está ligado entre si, isto de Lentes, só se produz com Impressão DLP...

Learn How to Make Your 3D Prints Truly TransparentPinshape Blog3D printing continues to advance in its ability to create visually accurate prototypes, but most machines are still unable to produce optically clear parts. In this post, you’ll learn why 3D printers struggle to make objects clear straight off the build platform, and you’ll discover 3 techniques for making optically clear parts.

Why Aren’t 3D Prints Clear?

A smooth lake reflects surrounding objects, but when agitated the image warps and distorts. On a smaller scale, this is the effect that causes 3D prints made in a clear material to appear slightly opaque. Layers of a 3D print take on a slightly oval shape creating small gaps between layers that refract light and distort the image.

The above graphic from Taulman3D shows how light travels and bounces inside the layers of a 3D print. The purpose of the techniques you’ll learn today is to either add or subtract material from the print in order to flatten the layers and allow light to pass through without refraction.

https://pinshape.com/blog/learn-make-3d-prints-truly-transparent/

E para os Fabbers, os Entusiastas da Electrónica, e os Sucateiros de Ocasião, eis uma pequena caixinha para soldarem e des-soldarem em todo o lado...

É bom!

The Back Pocket Soldering Kit

Bean_MD

As a budding electronics enthusiasts, I made alot of things on my farm autonomous. With that came the problem that my soldering skill is a bit dodgy.

Recently I had to repair a few of these dodgy solders, which means I had to disassemble and take the part with me to the workshop.

This is a 10km + drive.

So as it is said, necessity is the mother of invention.

This is my kit I can drop in my back pocket, in my cabby hole, I even have one in my sun visor.

https://www.instructables.com/id/The-Back-Pocket-Soldering-Kit/

Sem comentários:

Enviar um comentário