Isto é uma maravilha!

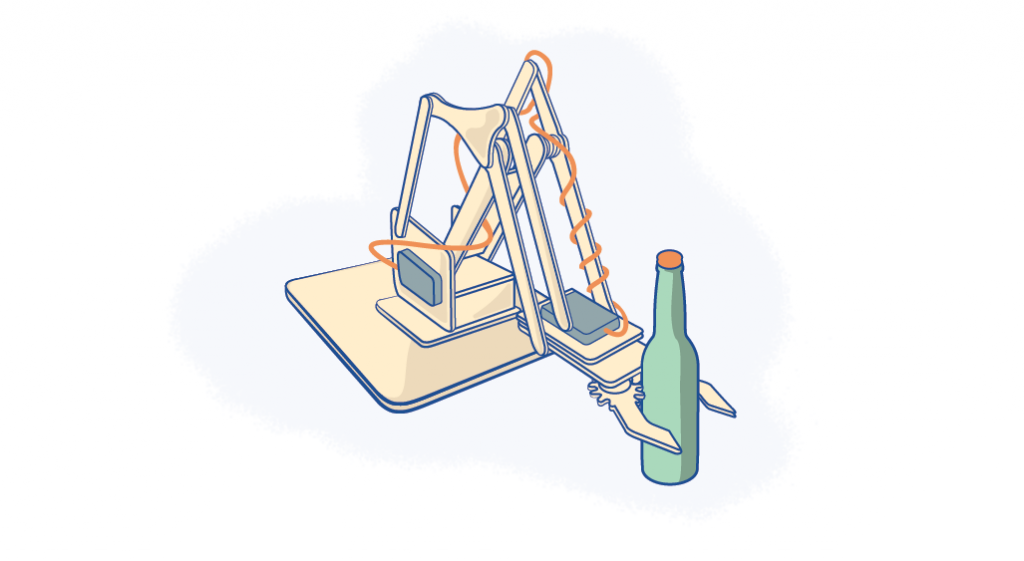

Só precisam de pousar uma destas máquinas no Material que quizerem trabalhar, e não há limite para o que possam fazer!

Mais portátil que isto, só a máquina seguir-vos de casa, como um Cão!

LOL

Já vai quase em 10 vezes a quantia necessária, só por isso, se vê o interesse que já despertou, e com toda a razão...

Quero uma.

Trailer video of Goliath CNC, a portable and autonomous CNC machine designed to make any idea of any scale, in every space.

Goliath CNC - An Autonomous Robotic Machine Tool for MakersSpringa

A portable robot that mills, cuts, and engraves to turn BIG ideas into tangible items with any materials and various CAD file formats.

https://www.kickstarter.com/projects/2130625347/goliath-cnc-an-autonomous-robotic-machine-tool-for/description

Tudo funciona, no papel, mas quando passa à Impressão 3D, surgem as dores-de-cabeça...

Cá vão mais 7 maneiras de editar e reparar os vossos Objectos em formato Stl, e todas elas, à borla, que é o mesmo que dizer, grátis:

7 Free STL Editors + How to Edit and Repair STL Files

Frederik Bedrich

How do I edit STL files? That is something any 3D printer owner sooner or later wonders. After all: Ready-made STL files are fine. But what if an STL file you downloaded lacks some features, is damaged or you need only a part of it? That’s when you need an STL editor.

https://all3dp.com/1/7-free-stl-editors-edit-repair-stl-files/

Acho que é um desperdício de tempo e dinheiro, fabricar em série, usando uma Impressora 3D...

Que pode muito bem fazer apenas UM Molde, para daí, se criar um número infinito de peças!

Por isso, este método é uma boa maneira de lucrarem a sério com a Impressão 3D:

How to make resin copies of a 3d printed object. Mold-Making Tutorial.

gordontarpley

Long, boring video about taking a 3d printed part and making a mold of it. So far, all of my 3d printed parts have been modeled in Autodesk's 3d Studio Max and printed at Shapeways.

https://www.youtube.com/watch?v=_VsAXHbzZeA

Há Materiais que se encontram nos sítios mais exóticos, e que servem mesmo a calhar para uma data de Engenhoquices...

Por exemplo:

Esta Loja de Artesanato dá-nos esta notícia dum material, uma Resina para embutidos transparentes, MAS, lembrem-se que podem fazer muita coisa com isto, de Cockpits para Modelos de Aviões, a Objectos Transparentes de toda a espécie, ou peças transpartentes:

NEW Easy to Use, No-Mix Resin Product!!!

Gifts of Avalon

We are delighted to be carrying a few different sealers and lacquers that open up all sorts of doors for creative projects using bezels, metal blanks and just about anything else your imagination thinks up!

The first product is a 3D lacquer that is FANTASTIC for sealing projects! It dries to a crystal clear finish that both enhances and protects your projects. And no mixing required! I use it all the time to protect my metals when I apply Gilders Paste or do embossing.

https://giftsofavalon.wordpress.com/2012/07/31/new-easy-to-use-no-mix-resin-product/comment-page-1/#comment-36

Se leram tudo isto até aqui, cá vai a recompensa, uma grande ajuda, como aproveitarem as vossas Impressoras 3D para substituír toda a espécie de peças que já não há, ganhando alguns cobres, e a admiração de muitos que ainda acham essas Impressoras 3D um "Brinquedo"...

How to Make DIY 3D Printed Parts for Just About Anything

Frederik Bedrich

We’ve all been there. You fiddle about with a gizmo or furniture piece of some sort in the home and a piece just snaps off. Shoddy flimsy plastic is the culprit, and the irritation it brings is endless. Gluing the piece doesn’t help, and you resign to living with the original doodad as a shadow of its former self; functionally fine, probably, but still not quite right.

What if we were to tell you that there’s an answer to replacing such non-essential but easily missed parts? It’s rather simple — make it yourself! With the lowering in costs for personal home 3D printing, and the rise in competitively priced print bureaus, acquiring replacement 3D printed parts is a cinch.

So settle in and read along as we outline the ins-and-outs of creating 3D printed parts for games, toys and other such home objects.

https://all3dp.com/diy-3d-printed-parts-spare-parts/