Aqui está uma máquina bem intrigante, com um mecanismo diferente, que eles dizem ser mais rápido e seguro, e parece mesmo ser assim...

E ainda vem com 3 meios de ser usada;

É bom!E ainda vem com 3 meios de ser usada;

- Como Impressora 3D

- Como gravadora de Alumínio

- Como fresa de plástico

3D printer SkyOne

3dlaboratorio

Industrial 3D printer SkyOne is meant for printing by up-to-date plastics with melting temperature up to 260 °С. Fused deposition modeling technology (layer-by-layer formation of an object from as fused plastic) is behind a concept of its operation. The printer is realized according a coupled design SCARA (Selective Compliance Assembly Robot Arm), two motors control levers, which move an extruder in XY plane. Feeding along the Z axis is realized by a ballscrew transmission. Scheme SCARA provides an advantage in printing speed over printers, which use Cartesian ordinates. But at the same time the software for 3D printer SkyOne is much more complicated than for printers constructed according a standard design.

https://3dlaboratorio.es/eng/3d-printers.htm

Às vezes, é mesmo útil ter uma ferramenta ou um parafuso magnetizados...

Outras vezes, é bem chato, só atrapalha!

Pois aqui aprendem como tanto magnetizar, como a fazer o contrário, desmagnetizar, e é um instructable bem porreiro:

Tool Demagnetizer and Magnetizer

tonyfoale

Tools sometimes get magnetised, this can be both useful and undesirable depending on the type of tool and the actual job that you want to use it for. For example there are times when having a magnetised screw driver is helpful to hold a screw when you need to put it in an awkward place but unless you want to do that it can be a disadvantage because it will attract any ferrous swarf, nails and screws nearby. Drill bits are a tools which you would not want to ever be magnetised, it will get covered in chips when drilling ferrous material.

That said, we can see that a means to magnetise and demagnetise tools and other objects like vernier calipers would be a useful workshop addition. To magnetise a tool we only need subject it to a strong uni-directional magnetic field and to demagnetise we subject the object to an alternating magnetic field.

https://www.instructables.com/id/Tool-Demagnetizer-and-Magnetizer/

Para montarem as vossas Engenhocas em secções separadas, e juntá-las, sem cola, ou também para repararem uma Impressão com falhas, podem usar este belo deste método, a soldagem por Fricção!

Algo, portanto, que vos vai poupar a muita re-impressão maçuda...

E parmite ainda uma Engenhoca em várias partes!

PLA Welding – How to Fuse PLA Seams and Cracks

Tian Ooi

PLA welding is a way to fill in gaps or “glue” 3D prints together.Using a power drill with a small piece of PLA filament instead of a drill bit, the rotating filament is pushed against the 3D printed plastic. This generates friction, which heats up the filament and softens it. The filament is then free to fill in a crack or weld plastic together. After cooling, this creates a strong bond, as if it had been part of the piece all along.Inspired by friction welding, a welding technique typically used to fuse metals, PLA welding applies the concept of utilizing rotational friction to plastics instead. Friction welding is often used in industry to join dissimilar materials at more stable temperatures than other welding methods. Applications include the aerospace and automotive sector, joining together turbine shafts, car frames, and more.

Algo de bem ùtil, fabricarem o vosso próprio Carvão, a partir do super-económico Rocket Stove, que aproveita TUDO duma Combustão, o Comcustível, os Gases, as partículas, tudo!

Charcoal RetortKuzmanic

I have had a couple of attempts making charcoal using 44 gallon drums and they have worked okay, but needing a new project after buying a mig welder, I decided to make a retort.

The theory of a retort is that you heat the wood to be made into charcoal up to a point where it starts expelling all of the wood gas and impurities, which is then fed back into the fire to keep the process going.

After reading up and watching a number of videos on rocket stoves and retorts, I decided to make one with the idea of combining the two into one rocket stove powered charcoal retort.

https://www.instructables.com/id/Charcoal-Retort/

Se já têem o Fusion 360, podem idealizar algo, e passar à Fresa CNC, porque o programa tem essa funcionalidade, e aqui está como lá chegar, com um exemplo simpes:

Creating a Simple 3D Model on Fusion 360 and Creating a Toolpath MYDIYCNC

Tory MYDIYCNC

Hello there,

Tory at MyDIYCNC here. Today I want to show you how to use a very useful piece of software from Autodesk called: Fusion 360. With this software you can create simple 3D Models, to elaborate and complex 3D models.

What I hope to teach you today is how to create a simple model on Fusion 360, and then create a tool path in which you can then run the G Code on your MyDIYCNC machine or another CNC machine.

Let's get started!

https://www.instructables.com/id/Creating-A-Simple-3D-Model-on-Fusion-360-and-Creat/

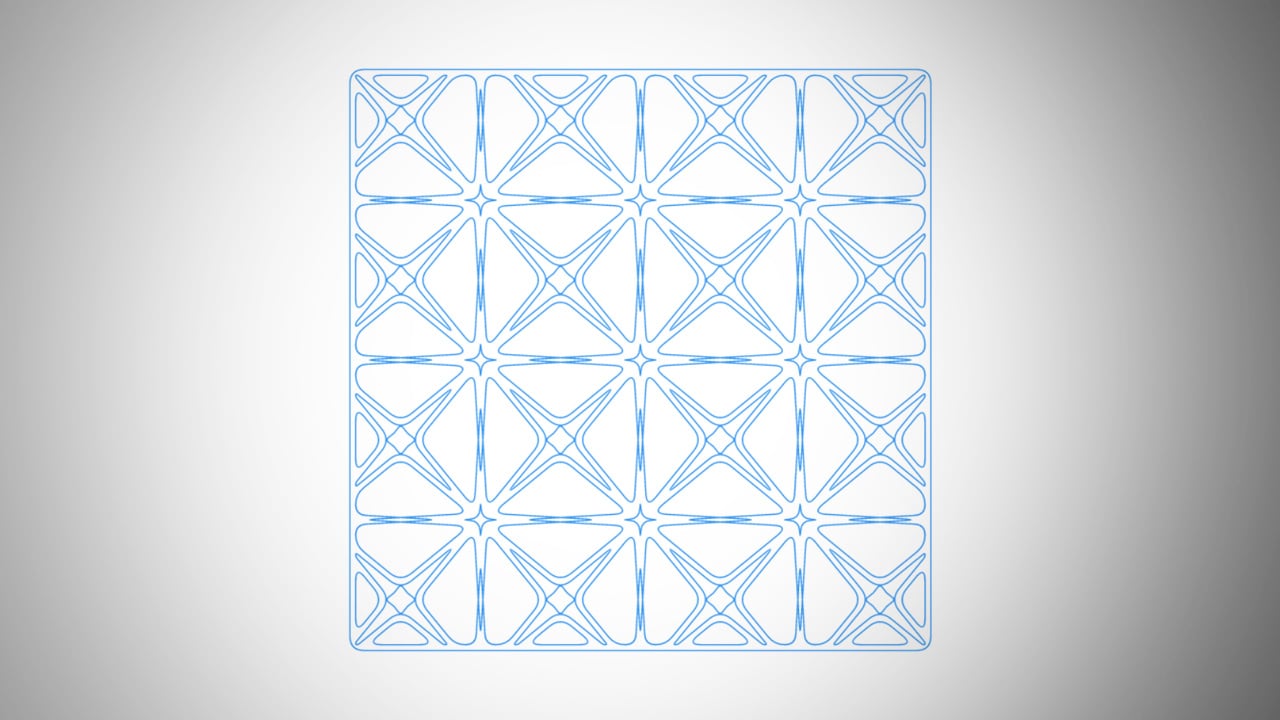

Para algo como desenhos repetivivos, cá está como fabricarem as vossas texturas ou mesmo Mosaicos, Grades, etc a partir duma App na Net:

[STUFF] Polygonia Design SuiteAll3DP

Offering possibly the simplest way to sketch repeating geometric patterns, this browser-based web app is a surefire resource for intricate 2D designs.We’re not ones for lattice room dividers, but after spending some time toying around with Polygonia Design Suite, it’s just a matter of time before the All3DP office is a maze of fancy laser cut obstacles. A browser-based vector drawing tool for quickly creating geometric patterns, Polygonia is the result of a visit to the Smithsonian and a smattering of high school math and software engineering by its creator, David Kaufman.Through the simple UI of an online design app, you can sketch out simple line inputs which get instantly translated into rad looking tiled designs. Multiple parameters allow you to customize the design to suit your project and a variety of output formats including SVG and PNG give flexibility for further design software you use after.