Eis algo para vos ajudar a levar as vossas Engenhocas, no campo do Hardware, Startups, partilhar ideias, e contactar Industiais...

Uma grande ajuda, para concretizar coisas, penso eu!

HARDWARE COMMUNITY

Hardware City closes the gap between hardware startups and contract manufacturersHardware Startups

Developing hardware products is Hard! Here you can find a community that can help you during the pipeline of industrializationCommunity of Makers

Makers are one of the most creative communities worldwide. We want to engage this community to stimulate the creativity and share of technical skillsIndustry

The step from product development to industrialization is the most difficult. We want to bridge the gap between hardware startups and the contract manufacturers

Um Estroboscópio a partir dum LED?

Algo de útil para Fotógrafos, Engenhocas, Curiosos, e Cientistas, por isso aprendam, que é bom.

Make Your Own LED StroboscopeGreatScottLabIn this project I will show you how the stroboscopic effect works and how we can use it to determine the RPM of a motor. Also I will be showing you how to create a simple LED stroboscope at home by utilizing an Arduino or a 555 Timer circuit. Let's get started!

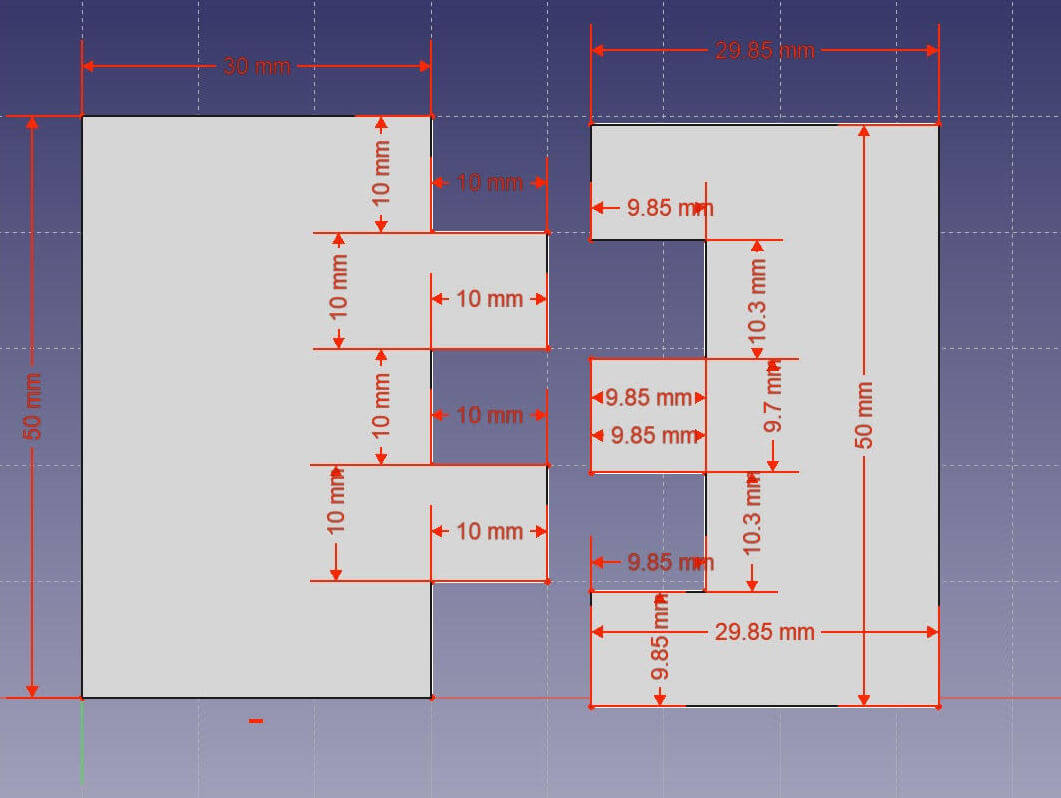

Mobília, a partir da ideia, passando ao CAD, e depois ao CNC, passo a passo, ora aqui está algo de porreiro para os Designers!

CNC Furniture: From Sketch To Prototype Using Rhino & Grasshopper!

Ezequiel Lopez

About Carlos and Modifile

Carlos Travaini is the lead designer at Modifile.com. He's an Argentinian that moved to Venice, Italy many years ago and is constantly busy alternating between private projects he gets hired for and his new website.

Intrigued by how he's able to mix all the elements that enable him to create all his fun and very original furniture pieces, I asked him for a favor: I wanted to get to know his creative process. Note that most of the times this is a very private process and many artists simply won't let you into that space, but Carlos was gracious enough to let our cameras in not only during the sketching portion but the entire process, from sketch to prototype production.

https://www.shapediver.com/blog/cnc-furniture-from-sketch-to-prototype-using-rhino-amp-grasshopper

Aprendem aqui como dobrar a eito, Tiras de Metal, usando um pouco de Faça Você Mesmo:

Homemade Mini Bend Brake

Improbable Construct

In this Instructable I will show you how I made a Mini Bend Brake to bend some 1/16" aluminum.

I needed to make clean straight bends in strips of aluminum for my Hidden Bookshelf Light Switch.

I had pretty good luck bending the aluminum in my bench vise, but it was hard to keep the bends square and even.

So, this is what I came up with.

https://www.instructables.com/id/Homemade-Mini-Press-Brake/

O Tempo passa...

Se o vosso Software Marlin precisa de ser actualizado, este nosso amigo explica como se faz.

Easily upgrade the Marlin firmware on your kit 3D printer!

Thomas Sanladerer

Ever wanted to get rid of the buggy or outdated version of the Marlin firmware that shipped with your printer? Just update it to the most current one! I show you how to set up the mainline Marlin firmware on your kit 3D printer using the Arduino software package.

https://www.youtube.com/watch?v=lAKyZd63_ns