Não há muitos Divulgadores e ao mesmo tempo, autênticos Professores como este...

Um Génio!

Na sua Série de Vídeos, aprende O QUE PRECISAM, para cada caso, mas vão absorvendo uma data de material que doutra maneira seria maçuda e sonorípora...

Acreditem, o ar descontraído esconde um menino que aprendeu Engenharia para Operador de CAD, 3 gigantes livronhos, como se não fosse nada, porque era preciso saber muita Matemática, e ele já a sabia, à vontade!!!

Como se não fosse nada!

.

Um Génio!

Na sua Série de Vídeos, aprende O QUE PRECISAM, para cada caso, mas vão absorvendo uma data de material que doutra maneira seria maçuda e sonorípora...

Acreditem, o ar descontraído esconde um menino que aprendeu Engenharia para Operador de CAD, 3 gigantes livronhos, como se não fosse nada, porque era preciso saber muita Matemática, e ele já a sabia, à vontade!!!

Como se não fosse nada!

.

Engineering Principles for Makers Part One; The Problem. #066Jeremy Fielding

A easy to follow strategy for designing and making stuff with a focus on machines. Turn your idea into a real "thing". I call part one my “Dr. Farm“ Method.

My version of the basic design engineering process.

https://www.youtube.com/watch?v=FHhXbz1K0k0

Ora cá vai esta muito satisfatória máquina de criar Molas e outras coisas, a começar pelo altaente satisfatório Vídeo, algo que faz mesmo falta ao Engenhocas, e uma data de vezes...

Spring Making / Wire Bending Machine

jiripraus

Well, this machine is not only about making springs. It is a wire bending machine capable of bending 0.8/0.9/1 mm wire into any 2D shape. But yeah, the coolest thing I was able to make with it so far was the spring. How cool is that?

The main goal was to make it quite precise. Other DIY wire bending machines are not very precise and their bends tend to have quite a big radius. I like to work with nice sharp bends!

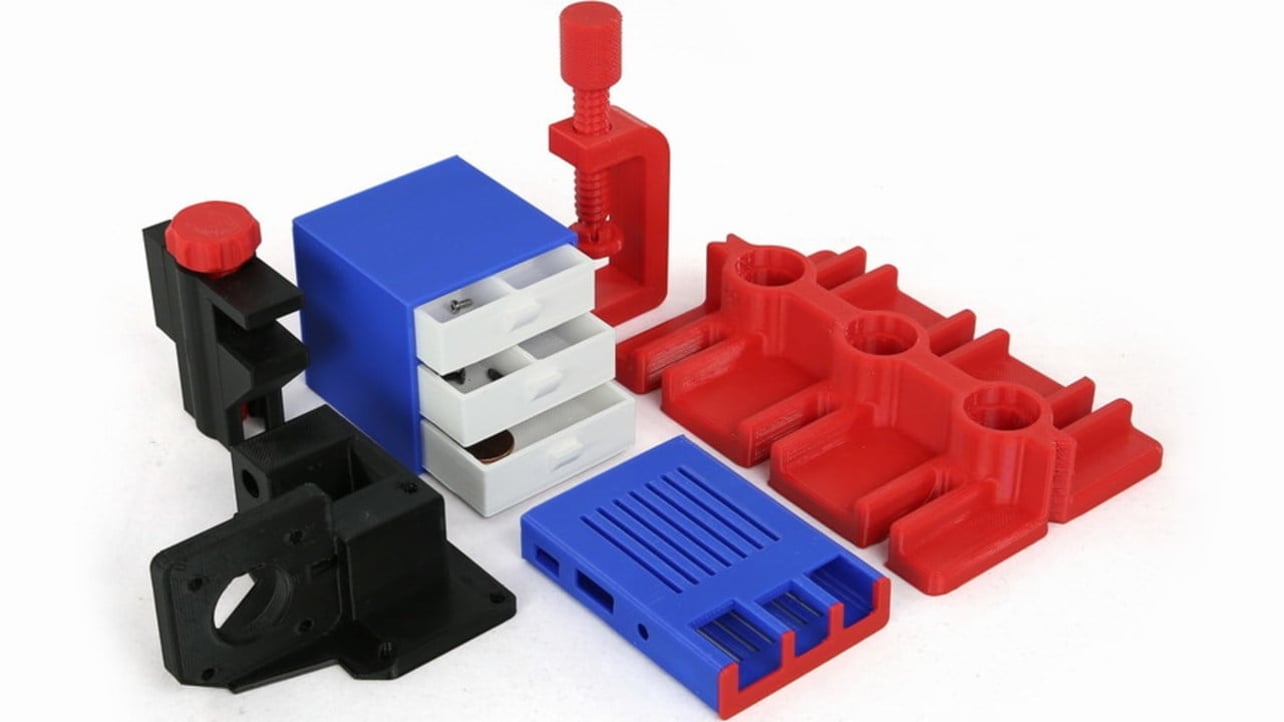

The second goal was to make it as easy to build as possible with commonly available parts and components. All the structural parts are 3D printed and all the metal parts are available in most of the hardware stores.

https://www.instructables.com/id/Spring-Making-Wire-Bending-Machine/

Um Tele-Controle feito por vocês, usando nem menos do que um Arduino...

DIY Arduino Radio Controller || Remote Controller || Part 1Aatik's lab

You might have played with a lot of rc cars and probably want to make one by yourself but one problem you will face is from where to get the desired transmitter and receiver so in this video i will show you how to make a arduino based transmitter and receiver with the help of nrf24 radio

https://www.youtube.com/watch?v=ctHnHsukRAs

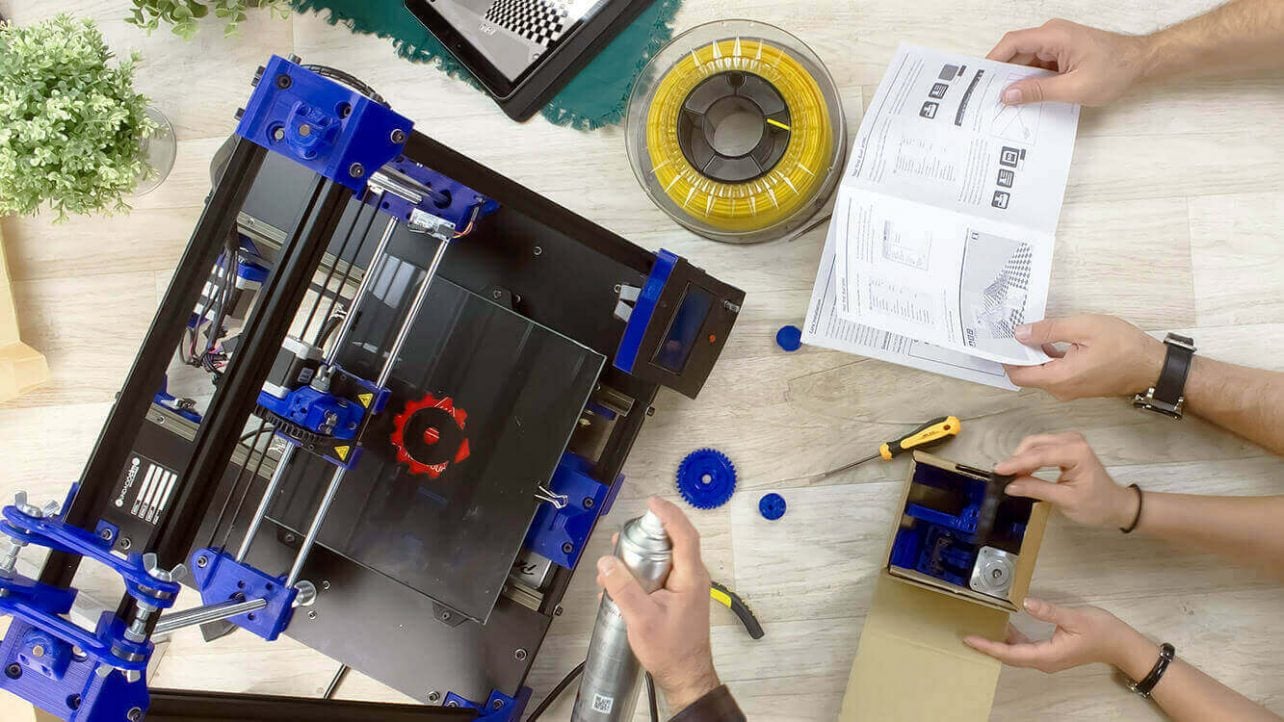

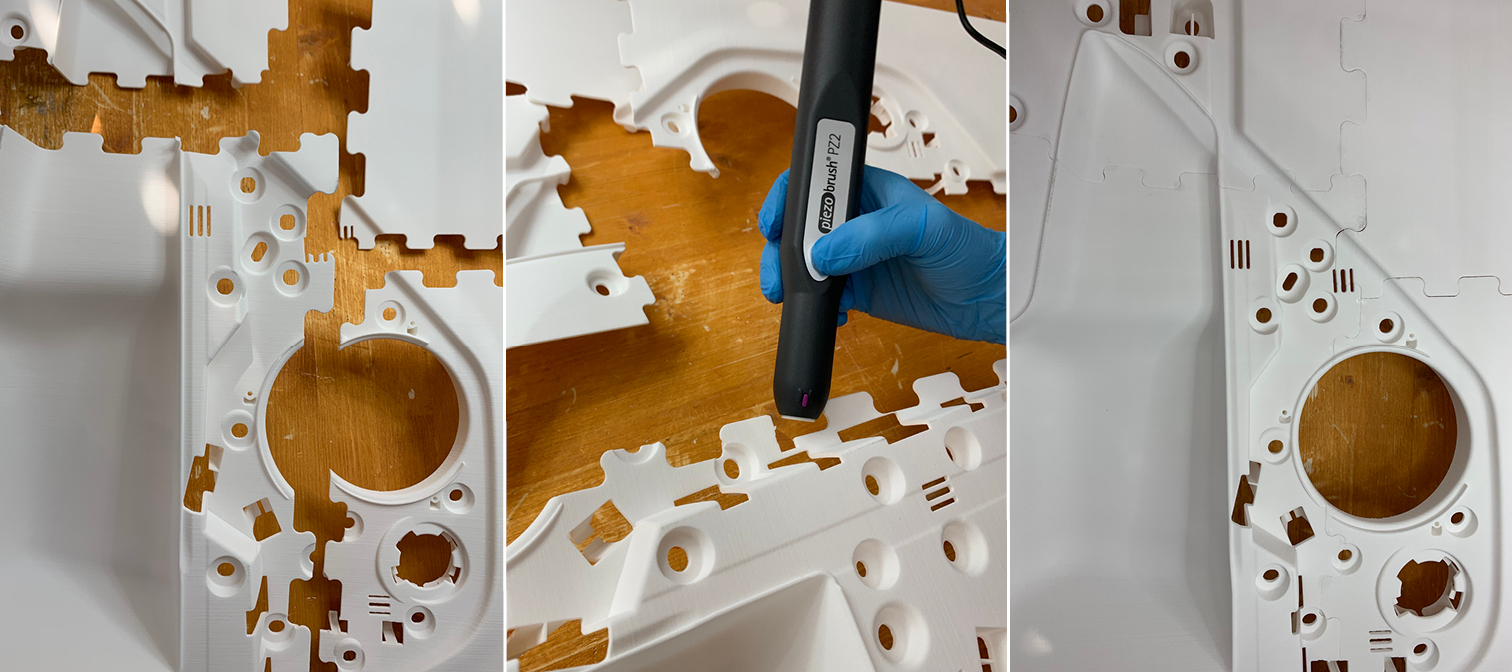

How to Create a Large 3D Printer Using a Smaller 3D Printer - "Project Locus"redhatman

From those that own 3D printers, to those who simply are just curious about their capabilities, one topic that comes up rather frequently is the idea of "Printing another 3D Printer". Now this may not be 100% possible when considering components such as the electronics, however, nearly every 3D printer today in the open source community utilizes to some degree, 3D printed parts in it's construction. From fan mounts to spool holders, a person can spend a few minutes searching the web, and likely find a suitable design to use on their own printer. This has proved to be very useful, especially for those who love to build, modify, and design their own machines.

https://www.instructables.com/id/How-to-Create-a-Large-3D-Printer-using-a-Smaller-3/

Que tal uma Micro-Fresa para a Oficina, para metais mais macios como Alumínio e Bronze?

Faz jeito:

Benchtop Micro Milling MachineHonus

This is a micro sized benchtop mill that is suitable for milling small parts in soft metals such as Aluminum and Brass. While it is a manual mill it wouldn't be too difficult to convert it to CNC by adding suitable stepper motors and a CNC controller.

The travel specs are:

X axis- 150 mm

Y axis- 75 mm

Z axis- 150 mm

This design uses off the shelf assembled linear slides and 80/20 Aluminum extrusion for simple assembly and accurate alignment. The beauty of this design is its modular nature- you can make it any size you want and it's super easy to build.

Be sure to check out the build notes on all of the enlarged images!

https://www.instructables.com/id/Benchtop-Micro-Milling-Machine/