Agora, podem comprar uma cortadora CNC de Jacto-de-Àgua, e cortar tudo aquilo que as máquinas Laser não podem!

Isto corta tudo, Metal, Cerâmica, Plástico, Policarbonato, uma limpeza...

Corta até 6 mm em aço Inox, e pode cortar até 25 mm, em tudo o resto!

6 mm in Stainless Steel, up to an Inch in other Materials.

Tinijet — Affordable Waterjet Cutting At HomeJames HobsonWhile laser cutting remains the dominant force for rapid prototyping anything made of plastic, MDF or wood, the real holy grail is the ability to cut metal — something most laser cutters are just not capable of.

In the industry, this is done using extremely high-powered laser cutters, plasma cutters, or water jet cutters. All of which are very pricey equipment for a hacker. Until now anyway. Introducing the Tinijet, the missing tool for affordable water jet cutting.

We first covered this project a few years ago when it was just a university research project called Hydro — it’s since evolved immensely, and will be available for sale very soon.

Aprendam, em 5 Lições, como se faz, para evitarem muita ferramenta estragada, cortes vários e etc...

METALWORKING CLASS

randofo

Working with metal is a challenging, yet rewarding, skill.

In this class, we will go over the very basics of metalworking including, cutting, drilling and finishing.

This class is designed for people with absolutely no prior experience ever working with metal. It will give you the knowledge and confidence to move on to more advanced metalworking topics.

https://www.instructables.com/class/Metalworking-Class/

Ora cá vai um Canito-robot, para que não vos falte nada!

You can make your Arduino, your own Pet, with this DoggoBot.

Kewel!

DoggoBot Version 1

makerinchief

Ever since I started programming Arduinos, I wanted to build a robot using one. I also want a dog. However, living in NYC makes it tough to take care of a dog. So after hours of watching videos of robots and dogs, I decided to put my phone down and build myself a pet!

I present to you find readers, DoggoBot Version 1! I created a 4 legged walking bot which can be build with cardboard and hotglue. The electronics are simple and can be ordered from Amazon. However, I noticed the links from Amazon tend not to last very long so the links provided are from websites which routinely carry the items. If you want to get them from Amazon, simply enter the name of the item in the Amazon search bar. You can definitely get a lot of these items cheaper on Amazon then directly from the websites provided.

https://www.instructables.com/id/DoggoBot-Version-1/

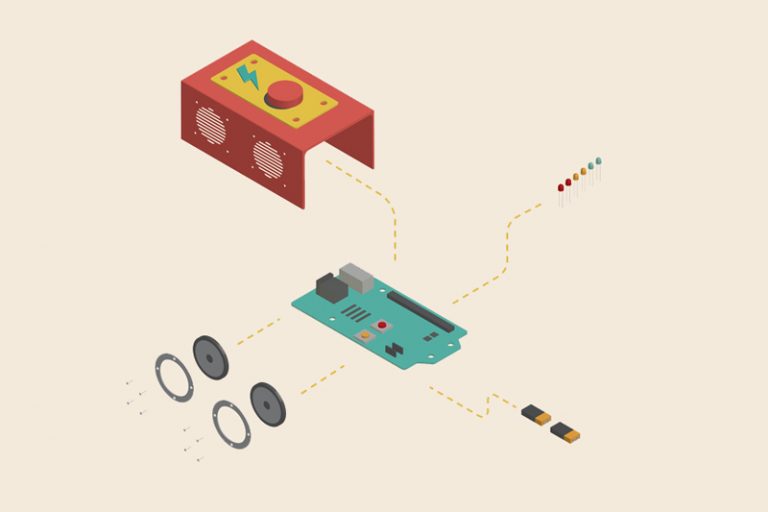

Electrónica sem uma caixa que a envolva, é apenas desleixo...

E acidentes à espera.

Evitem muita fumarada, encapsulando as vossas obras-primas numa caixa bem-construída:

No use making your wonder-thingamajig, just to have it taken apart or shorted...

To avoid the magic smoke, learn how to make an adequate encasing:

Your Guide To Making Electronics Project BoxesDJ HarriganDesigning And Laser Cutting Electronics Project Boxes Just Got Easier With This Must-Have Tutorial

You’ve just made something great: It blinks, it whirrs, it speaks in tones, it’s voiced-controlled and it’s “cloud connected” (of course). And now this assembled heap of your own design is waiting on your desk for the final touch.

Whether you are making a product for sale or prototyping your brand’s next show-stopping piece of promotional swag, you probably want to not only keep this electronic creation alive for years to come but also add context and personality to your product and draw fewer eyes as you ferry it through airport security. How? By making a robust electronics project box to house and protect your hard work, of course!

Uma Máquina de berlindes que podem imprimir em 3D?

É preciso dizar mais? MUÁHÁHÁHÁHÁ!

FAÇAM UMA!

A Marble Machine you can 3D print!

Need I say more? MEWAHAHAHAHAHA!

GO THERE!

Marblevator Mini, Loop.gzumwaltI had to dust off my physics textbook for this one...How fast is too fast for a marble machine? Well, check out the video "Marblevator Mini, Loop, High Speed Test", at 324,000 marble runs per day, it is indeed the fastest marble machine I've ever designed."Marblevator Mini, Loop" is not quite as "mini" as my previous Marblevator Mini designs, but is still quite small, and features a 7.5mm radius loop with a tapered auger lift. Using a few relatively simple physics equations, the height of the entrance ramp (H) is determined by the simple equation H = 2.7R (where R is the radius of the loop). My desire to keep the model small determined the loop radius (7.5mm) and ball bearing diameter (8mm). And to add friction compensation, especially for a 3D printed track printed in this orientation, I increased the height of the ramp over the calculated height of (2.7 * 7.5mm) or 20.25mm.In the video "Marblevator Mini, Loop Stress Test", the stress test ran over 29 hours and is still running. The auger rotates at approximately 75rpm which in this test translates to 75 marble runs per minute. At this rate, Marblevator Mini, Loop has executed (29 * 75 * 60) or 130,500 marble runs without loosing a marble.