Isto é importante.

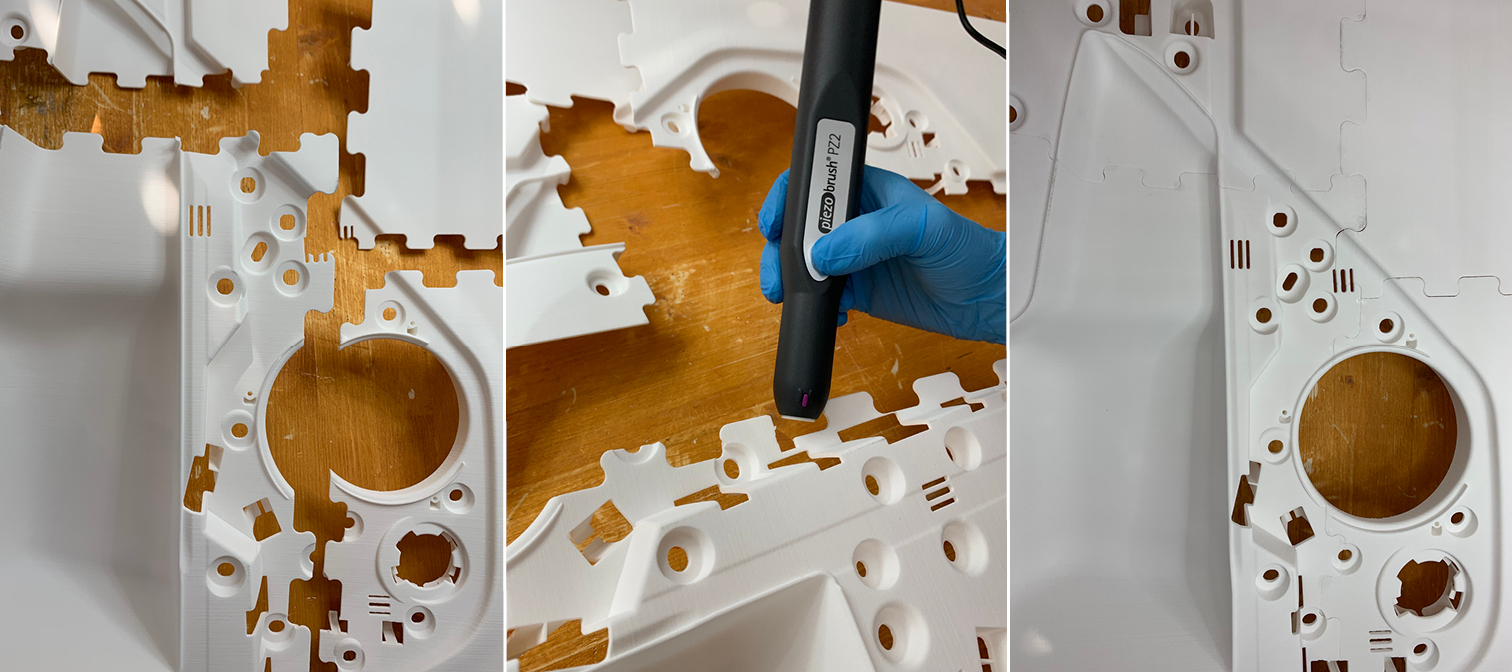

Porque assim, com este acessório manual, podem criar à vontade, sem problemas nem de tamanho, nem de cores diferentes...

Basta SOLDAR as peças, com este método de Plasma Frio.

Impressionante!

IS PLASMA THE MISSING LINK IN ASSEMBLING 3D PRINTED PARTS?UMAIR IFTIKHARCreabis, a Kirchheim-based 3D printing service bureau, is using Relyon Plasma’s piezobrush PZ2, a handheld cold plasma device, to bond 3D printed parts.The piezobrush PZ2 uses plasma to activate surface particles of a substance which strengthens the adhesion between joined parts. With a strong bond between assembled 3D printed parts, it is possible to manufacture large-sized sturdy components on small sized 3D printers.According to the CEO of Creabis, Ralf Deuke, plasma-aided bonding will lead to more novel applications in 3D printing.

Peguem numa Raspberry PI, e numas coisitas mais, e fazem o vosso próprio Computador Portátil todo manerinho, que cabe num bolso, dobrado!

É bom!

Make a Portable Computer Using a Raspberry PiTylerJohnson

Have you ever wanted a portable computer you can take with you? This is the easiest way to build your own. For those of you who do not know what a Raspberry Pi is, it is a complete computer about the size of deck of cards that can run many different kinds of Linux. This portable computer will be complete with a screen, keyboard, wifi, and a battery. This is just to show how to make the components work on battery, this indestructible does not have instructions for building a case. There are a lot of interesting ideas for cases and I did want to limit anyone's options. I tried to find the easiest way of making a portable all in one battery powered computer.

For this project you will need to be comfortable doing electrical soldering and desoldering; if you are have not done electrical soldering before, there are many tutorials online.

https://www.instructables.com/id/Make-a-Portable-Computer-Using-a-Raspberry-Pi/

Para essa história do IoT, Internet of Things, podem desenvolver os vosso Porjectos, à brava com este Kit, Azure Sphere por isso, cá segue o Anúncio da coisa, mas atenção, podem até receber o Kit GRÁTIS, se forem, seleccionados...

Azure SphereWe're partnering with Microsoft and Avnet to test their new, highly secure IoT dev kit, the Azure Sphere MT3620 Starter Kit. We'll be hosting multiple Design Challenges around this kit, as well as a RoadTest, webinars about using it for prototyping, and more, so we'll provide everything you need to get started with this IoT solution!If selected for the RoadTest, you will receive the kit for free. Follow this group and watch for Design Challenge news.

Sabiam...

Que podem gravar em METAL, até com as minísculas gravadoras Laser que há à venda, por aí?

Podem, MAS com uns truques.

É preciso um tratamento Químico, e este Instructable, foi ver quais os melhores para quais metais, por isso, têem a papinha toda feita!

Laser Engrave Metalbrichtl

Being able to engrave metal was one of the main reasons, why I got a laser cutter.

In this instructable I am going to show you some of my experiences.

Please share your results and experiences in the comments, I would love to learn more about engraving metals.

A word of warning: The process of engraving metal after applying an agent to the surface is patented. So please inform yourself, before doing so commercially.

https://www.instructables.com/id/Laser-Engrave-Metal/

Mais uma forma de fazerem Scan 3D, com uma vulgar Câmara digital, todos os passos, programas e aparelhos necessários:

3D Scanning Yourself in High Resolution With a Camerashuang peng

In this instructable, I'll share with you how to create a 3d model of yourself with a camera. Then clean up, fix the mesh make them printable models.

Things you'll need:

- A camera (or a phone with camera function)

- Autodesk Remake

- Autodesk Mudbox

- Geomagic studio (optional)

https://www.instructables.com/id/3D-Scanning-Yourself-in-High-Resolution-With-a-Cam/

- A 3d printer (if you want to print them)