Se precisam deste Instrumento de Cálculo, a Régua de cálculo pessoal, versão Circular já o podem fazer, com um humilde CD!

É bom!

CIRCULAR CD SLIDE RULE

cparedes2302

Hello Everyone!Keeping it up with my math helping tools and after I finished my straight Cardboard Slide Rule, I decided to make another slide rule but of much easier and fast construction. I decided to go for a simple circular slide rule. Just as the previous slide rule, the intention is to have middle school students built their own and use it to get numeric ability. I know there are several apps that emulate a straight and a circular slide rule, but if you are using your phone it would be much easier to use the calculator instead of the slide rule. My dream is to have the students “thinking and reasoning” again instead of relying so strongly on technology.The advantages of a circular slide rule is that the computing scales (C and D) of a 9.5 cm (3 3/4”) diameter tool are equivalent to a 30 cm (almost 12”) straight slide rule! So you can get a more accurate reading! The disadvantage is that as your scale is located closer to the center of the Slide Rule, the scale becomes very short and difficult to read.

O Petg, enquanto Filamento, está a ser muito mais utilizado, por isso, vai como o imprimir o melhor possível:

PETG Print Settings – How to Find the Best Settings for PETGMiroslav Sarcevic

PETG is short for polyethylene terephthalate glycol-modified. That could mean something to you if you’re into chemistry, but for the rest of us, it’s simply the most used type of plastic on the planet (in the form of PET). You can find it in plastic bottles, food containers, packaging, toys, kitchen utensils, and more common plastic products. In addition, this recyclable plastic can be injection molded, blow-molded, thermoformed, bent, cut, and in recent years, 3D printed.

We won’t go into the details of PETG chemistry in this article but will instead concentrate on 3D printing with it. Before we dive into printing tips, here are a few of the material’s characteristics:

- Glass transition temperature: 80 °C

- Density: 1.27 g/cm3 (which is higher than PLA and ABS)

https://all3dp.com/2/petg-print-settings-how-to-find-the-best-settings-for-petg

- Resistant against most chemicals (such as acids, alkali, and solvents)

Ao contrário das Fresas 3D, as Impressoras não imprimem em 3D MESMO, porque o Extrudor só move uma camada de cada vez, toda ela, sem a possibilidade de estrudar, e descer, e subir, num acompanhamento duma superfície curvada.

Mas está-se já a começar a fazer REAL Impressora, já, já!

Fantástico!

Achieve true 3D printing with non planar slicing

Teaching TechThis is the most interesting thing I’ve done with my 3D printer in some time. Instead of printing in a series of 2D planes stacked up to form a 3D shape (2.5D), this non planar technique creates geometry with true 3D tool paths that can eliminate the steps often seen on shallow surfaces. Based on the amazing Masters Thesis of Daniel Ahlers and the University of Hamburg, this development can be tried yourself if you are willing to put in some time to setting it up.In this video I’ll lead you through step by step on how to setup a virtual Linux machine on your PC, compile the custom version of Slic3r and then share with you my results. The future is bright and I thank people like Daniel Ahlers and Moritz Walter for leading the way.

E cá vai esta 3 em 1 para a Serra Circular, que vos vai ampliar a Ferramenta, com estes 3 Cortes adicionais, tão úteis, vejam o vídeo!

How to Make a Three in One Table Saw Sled || Taper Cuts- Jointer Sled - Miter Cuts

penaltyboxwoodshop

This video shows you step by step on how to build a three in one table saw sled. With this sled you can make taper cuts for table legs, edge joint wide boards, and make 45 degree cuts for projects like making picture frames. This sled can be helpful to any skill level woodworker!

https://www.instructables.com/id/Three-in-One-Table-Saw-Sled-Taper-Cuts-Jointer-Sle/

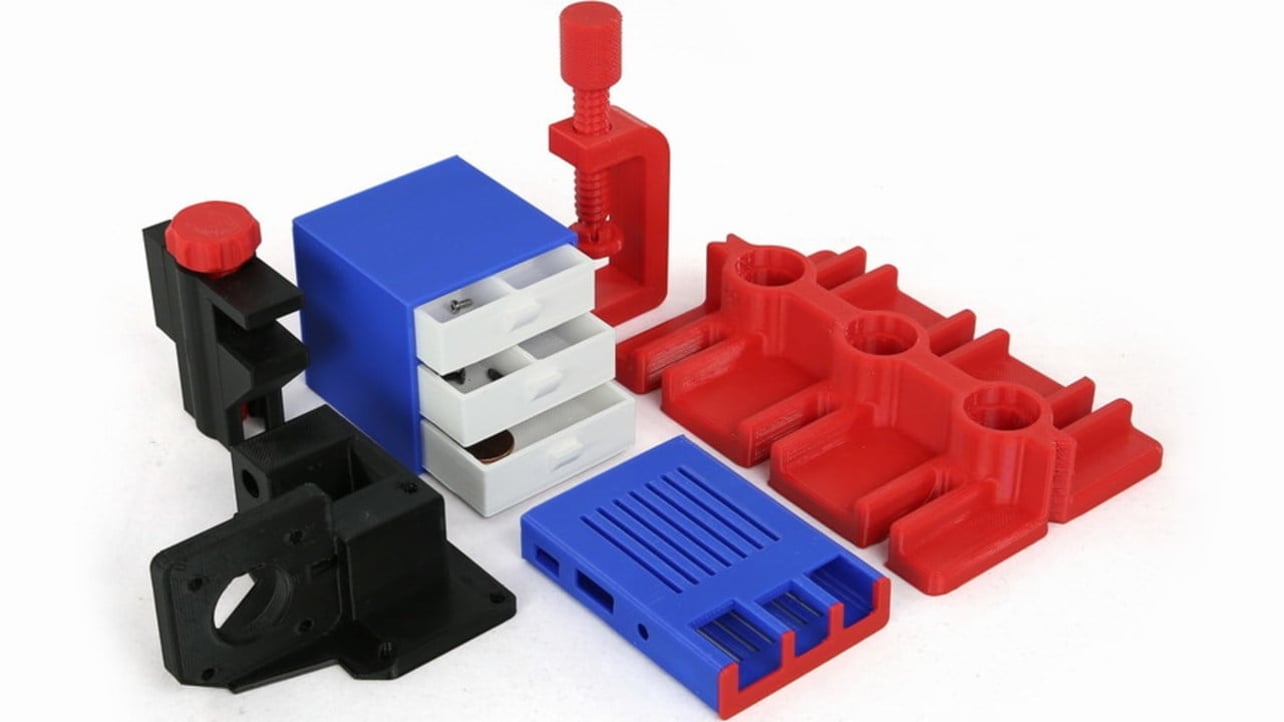

Mais Carpintaria, agora, uma coisa feita nas Impressoras 3D, está tudo inter-ligado, no mundo da Engenhocas...

Não quero que vos falte nada!

CNC Clamps 2mm (0.08 Inch) to 18mm (0.7 Inch)PatrickH101

Clamps for holding down your workpiece on a cnc router. The

clamps are designed for holding down materials with a thickness of 2mm to 18 mm.

I designed the clamp using Fusion 360.

There are 4 different sizes for the bolt that goes through, M5, M6 or 1/4 inch and for a special request M8 (The M8 version is not tested but should work though the sliding distance is a lot shorter).

Best is to use a washer on top.

The actual foot to hold your workpiece can rotate to adjust to the thickness of your material.

https://www.instructables.com/id/CNC-Clamps-2mm-to-18mm/

Sem comentários:

Enviar um comentário