A placa Raspi não pára!

Agora um autêntico Computador, Quad-Coore de 64 bits, e o que mais, a 1,4 GHz, vão ver à página deste Link as Especificações desta bela máquina!

Raspberry Pi 3 Model A+ Unboxinge14philIntroducing the Raspberry Pi 3 Model A+, the latest product in the Raspberry Pi 3 range.

Like the Raspberry Pi 3 Model B+, it boasts a 64-bit quad core processor running at 1.4 GHz, dual-band 2.4 GHz and 5 GHz wireless LAN, and Bluetooth 4.2/BLE.

The dual-band wireless LAN comes with modular compliance certification, allowing the board to be designed into end products with significantly reduced wireless LAN compliance testing, improving both cost and time to market.

...Algumas dicas que não são óbvias, e são mesmo essas as que nos tramam, quando não as sabemos...

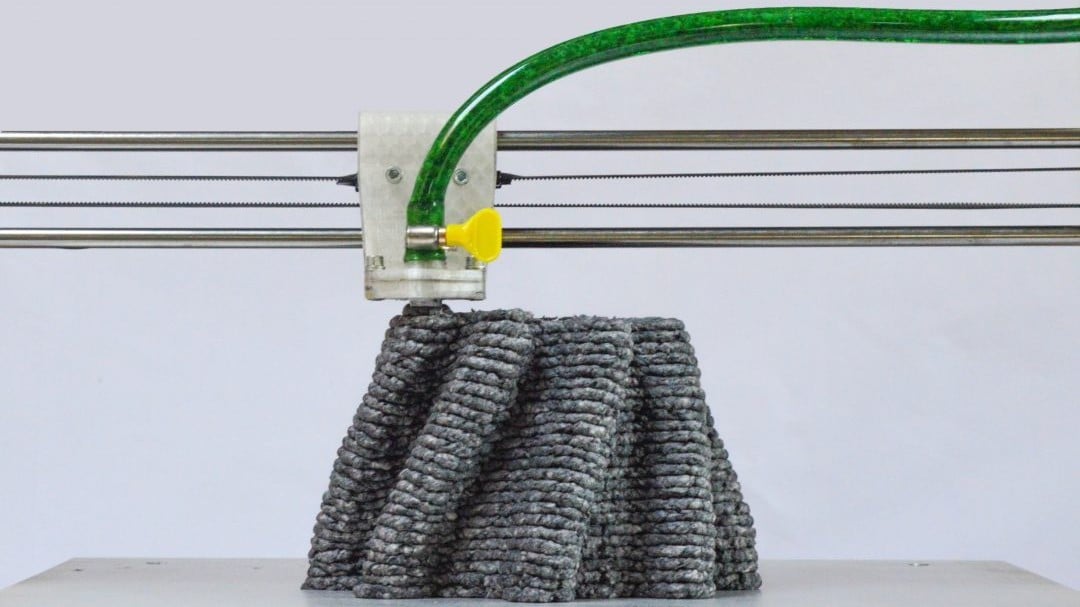

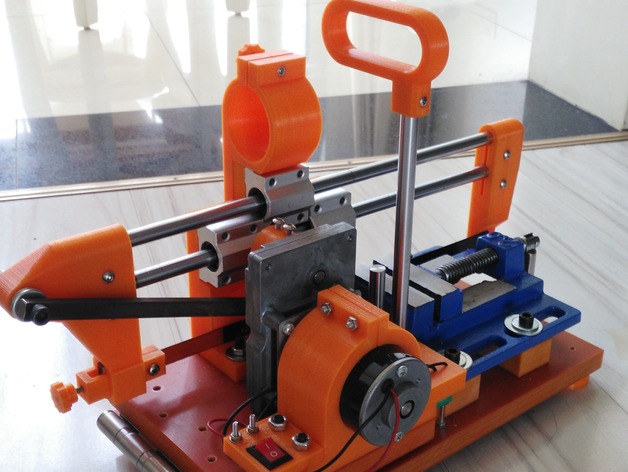

Saibam então como fazer uma caixa para as vossas Impressoras 3D, que permita uma temperatura estável, sem abafar a máquina, e mais!

Saibam então como fazer uma caixa para as vossas Impressoras 3D, que permita uma temperatura estável, sem abafar a máquina, e mais!

Dicas porreiras.

5 Tips for Building a 3D Printer Enclosure3D Printing NerdWhile at Printed Solid, I spoke to David Randolph about 3d printer enclosures. They sell a number of enclosures, and even white label their enclosures for other resellers. Knowing I tried to build one myself with Bill Doran, I asked Dave to give me his five best tips for building one!

MINI-SATÉLITES!!!

Muháháhá!

Malta Estudante, e Super-Geeks, aprendam como construír estes bichinos, mas para durarem, que lançá-los, não é pela UPS, ou pelos Correios.

Ainda... LOL

Maravilha.

ArduSat-1 and ArduSat-X launched from the ISS Picture credit: NASA

Build a CubeSat Satellite that actually works, Part 1: Make it ResilientBill Marshall

It’s such a great idea: students in schools and colleges inspired to become the next generation of Space engineers by building and orbiting their own satellite. But it’s not a new idea. The first amateur satellite, OSCAR 1 was actually launched in 1961 as a secondary payload - only four years after Sputnik 1. Project OSCAR continued with more launches until 1969 when the Radio Amateur Satellite Corporation (AMSAT) was formed to co-ordinate further activity. The OSCARs are primarily amateur radio communication satellites built by students in educational establishments worldwide. Three were constructed at Surrey University in the UK starting with UoSAT-1 (OSCAR 9) in 1981 then UoSAT-2 (OSCAR 11) in 1984 and UoSAT-3 (OSCAR 14) in 1990. The educational purpose behind these satellites was highlighted when a special purpose radio receiver with software for the BBC Microcomputer became available. In the late 1990’s the CubeSat was born when it was realised that thanks to microelectronics it had become possible to squeeze most of the functionality of an OSCAR satellite into a 10cm cube. Since the first one made it into Low-Earth Orbit (LEO) in 2003, many more have followed. But the failure rate has been high for two reasons: the stresses of launch can ‘break’ the CubeSat before it even reaches orbit, and the Space environment is very hazardous for delicate electronics once orbit is achieved. What can be done to increase the likelihood of success?

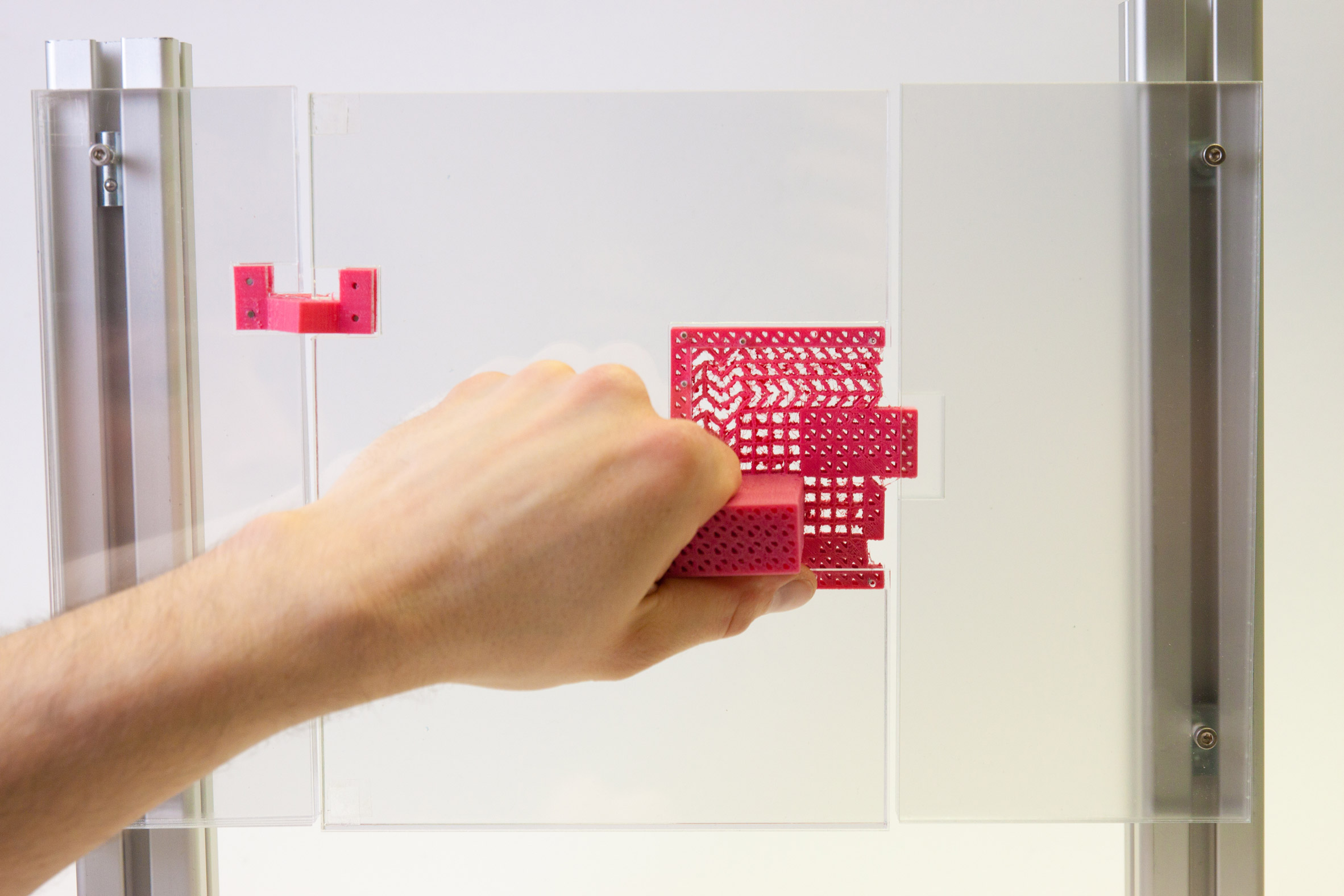

Para não ficarem piores da Vista, nem dos Pulmões, não se lixem, ao lixar à máquina, e usem mas é esta Caixa protectora, que a saúde é essencial.

E também é essencial à paz de espírito, uma Garagem limpa, para terem de ouvir a querida Esposa a ralhar à brava...

LOL

Garage Dust/Sanding Enclosure

corbor4shore

INTRODUCTION:

I have a very small shop in my two car garage. Unfortunately I have to share that space with two cars. When I am sanding, routing or drilling, dust seems to coat every surface in my garage, including my wife car. I was tired of washing my wife’s car so I needed to find a solution to all the dust I was creating. I did some research and found some sanding downdraft tables, but I couldn’t imagine those working without an incredibly powerful vacuum (which I do not have), plus they do not contain the dust jettisoned out. I then started looking at bead blasting cabinets and found that I liked the containment aspect of the cabinet but I needed the downdraft capabilities of the sanding tables, so I decided to create a hybrid.

https://www.instructables.com/id/Garage-DustSanding-Enclosure/

Aprendam 5 lições duma assentada, sobre como usar o humilde, mas tão útil, Tubo de PVC para uma data de coisas boas, cortesia da nodda amiga, audreyobscura, que não pára de nos surpreender com a sua creatividade:

PVC CLASSaudreyobscuraPlastic PVC is most commonly used by plumbers and very clever DIY enthusiasts. This material and pipe were designed to transport water, as it cannot wear out over time like rusting metal can. PVC is also structurally very strong. When parts are constructed properly, it can support structures that are hundreds of pounds!

This class aims to go over the material properties of PVC as well as the most common ways it is worked, machined, joined, and finished. You'll be inspired to create furniture, agriculture projects, and more after learning these simple techniques to work with PVC.