A pedido de várias Famílias, eis uma Zarabatana-Revólver para aumentar a Diversão inocente das Zarabatanas de Cones de papel, que todos já fizemos...

E agora, fazemos outra vez, prá Filharada, e atiramos com eles, também, "para mostrar como é"!

LOL

Pois agora, são 6 de cada vez, cortesia deste vosso amigo, para se divertirem com as vossas Impressoras 3D, com um projecto fácil de fazer, só 4 peças, e que se monta num instante:

Six Shot Blowgun

Edgar Castelo

3D model description

A Blowgun with a revolver's cylinder, 6 shots in rapid succession. It uses 20 mm PVC tubing, and it's just 4 pieces and a rubber ban, all easy to print and assemble.

A Blowgun with a revolver's cylinder, 6 shots in rapid succession. It uses 20 mm PVC tubing, and it's just 4 pieces and a rubber ban, all easy to print and assemble.

Some 3 and a half hours to print, 98*44*30 mm, the larger part.The rest is the PVC tubing;

One large PVC tube part is the barrel, and 6 smaller tube parts, along with 2 other printed parts, make the cylinder.

The last 2 are a Rubber band, and the cylinder holding piece, that holds the cylinder, but rotates.

Não só respeitador do Ambiente, (embora o PLA seja tão biodegradável, que mais, era comestível...), como, talvez, uma forma de ter um material de suporte, para impressoras de 2 ou mais cabeças, eis algo a seguir de perto...

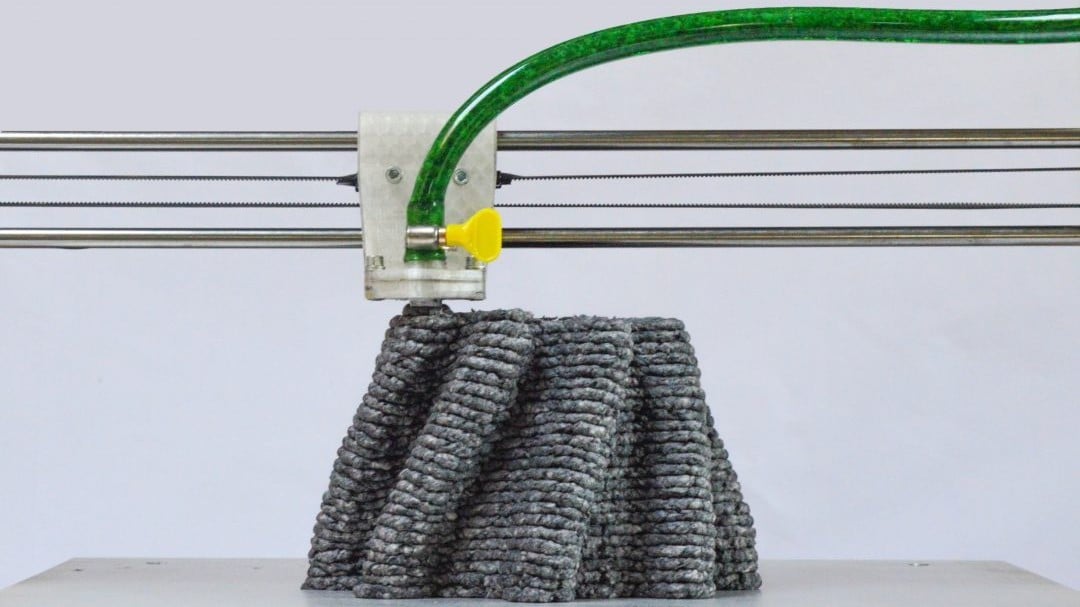

Imprimir 3D em POLPA DE PAPEL!

Designer Develops 3D Printer That Spits Out Wet Paper PulpTyler Koslow

Designer Beer Holthuis has developed the Paper Pulp Printer: a 3D printer that squirts out fascinating objects made from wet paper pulp. The project aims to give artists and designers a way to 3D print more sustainable objects.

3D printing is a marvelous and innovative technology that enables us to create even the most complex designs, but one issue that has concerned environmentally-minded makers is the excessive use of plastic materials. Sustainability is becoming a major focus for many 3D printing companies and enthusiasts, leading to the development of recycled materials and other more earth-friendly processes.

Taking inspiration from the mischevious kids that sat in the back of class shooting spitballs at one another, designer Beer Holthuis has developed the Paper Pulp Printer: a 3D printer that extrudes sopping wet paper. Using a bit of natural binder and wet paper, the designer created a 3D printer that could extrude a thick bead of pulp that could be built up layer-by-layer into a 3D object.

Eis uma muito boa razão para se ter uma Impressora 3D;

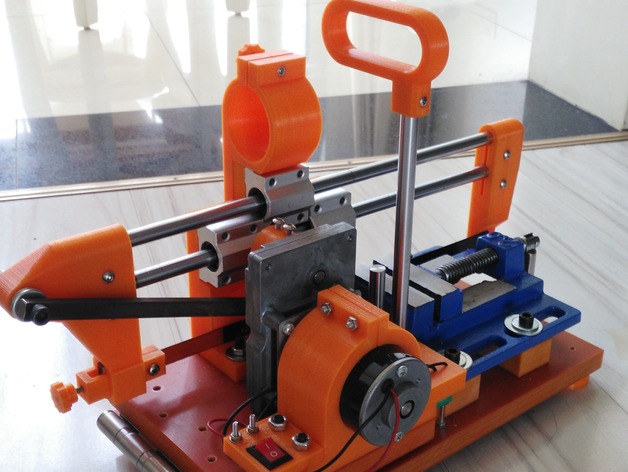

Fazer dela, UMA MÃQUINA QUE FAZ MÁQUINAS!

Isto vai-vos dar muitas ideias, e fazer uma Oficina, a partir de Filamento, é habilitar a Malta a ter outro nível de vida...

Ou, apenas, uns momentos bem passados!

Power Hacksaw by 3D Printer V4.0Tomlie_Xie MayThis time, I use bakelite to make the base. And the base reduced to 30cm. I have made two hacksaws for my friends.Now, I'm building the v5 hacksaw, its base is 270x135mm and more easy to make. i'll update the STLs after test finished.

Pessoal da Robótica, e Tele-controle, aprendam umas coisas sobre os Drivers, que impelem os Servo-motores a fazer o que lhes mandam:

556 Servo Driver

hombremagnetico

Servos (also RC servos) are small, cheap, mass-produced servomotors used for radio control and small-scale robotics. The are designed to be easily controlled: the position of the internal potentiometer is continually compared to the commanded position from the control device (i.e., the radio control). Any difference gives rise to an error signal in the appropriate direction, which drives the electric motor either forwards or backwards, and moving the shaft to the commanded position. When the servo reaches this position, the error signal reduces and then becomes zero, at which point the servo stops moving.

Radio control servos are connected through a standard three-wire connection: two wires for a DC power supply and one for control, carrying a pulse-width modulation (PWM) signal. The standard voltage is 4.8 V DC, however 6 V and 12 V is also used on a few servos. The control signal is a digital PWM signal with a 50 Hz frame rate. Within each 20 ms timeframe, an active-high digital pulse controls the position. The pulse nominally ranges from 1.0 ms to 2.0 ms with 1.5 ms always being center of range

https://www.instructables.com/id/556-Servo-Driver

Mais fiéis ao original, de certeza, que as Caravelas feitas com Pau-de-Fósforo, e com aplicações em toda a espécie de Espectáculos, Desfiles, e Filmes amadores, vejam como se fazem, no humilde cartão, Modelos convincentes...

Boeing 737-800 Build Out of CARDBOARDLalramsiamHello. Today, I am going to share with you, how I made an airliner (Boeing 737-800) out of CARDBOARD.This is my first instructable, so please forgive me if i post something incorrectly.

Sem comentários:

Enviar um comentário