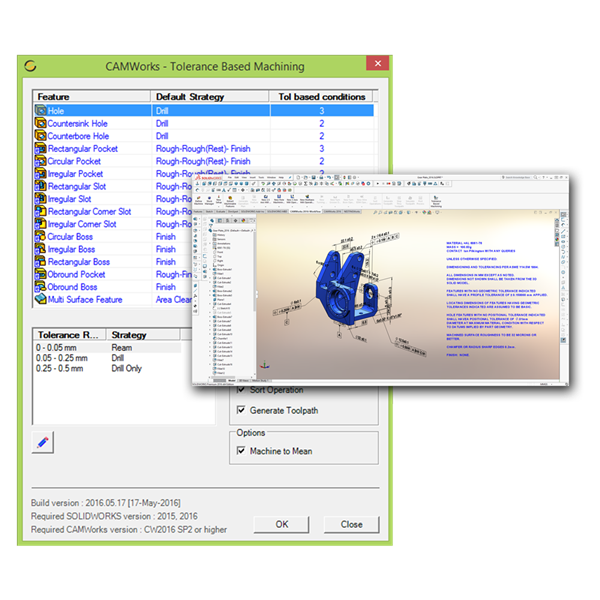

Um importante ajuda para quem quer transformar um Desenho 3D numa peça real, no Mundo Real, é este Programa, o CAMWorks...

Com a possibilidade de transformar um Objecto 3D numa série de Tarefas para Maquinação, com opções de nível de Tolerância e Acabamento, torna tudo mais fácil:

Geometric Continues to Revolutionize CNC ProgrammingResponsible for the content of this press release: Geometric Technologies, Inc.Geometric Continues to Revolutionize CNC Programming with a New Release of ‘Tolerance Based Machining’ for CAMWorks®Geometric Ltd., a global leader in 3D CNC machining software, today announced a new release of their revolutionary technology that uses SOLIDWORKS® 3D DimXpert and Model Based Definition (MBD) 3D dimensions and annotations to automate the programming of CNC machined components.CAMWorks was uniquely architected to reduce a 3D solid model into a set of discrete machining features, and apply a knowledge base that selects tools, feeds, speeds, and machining strategies to automate the creation of CNC toolpaths. Tolerance Based Machining dramatically enhances CAMWorks core architecture by adding the ability to read and react to non-geometric manufacturing information such as tolerances, surface finish, and other annotations in 3D models. This ability not only speeds up the CNC programming process, and improvements in quality, but also creates a much stronger design-to-manufacturing process for machined components.

Um Acessório que vos transforma um Berbequim numa Lixadora de Fita, é algo que já existe, mas não ao preço dumas Impressões 3D, e pouco mas.

E pode-se ainda usar apenas Madeira, torneada e furada, e então, ainda é mais acessível:

Power Drill to Belt Sander Conversion24Eng in 3D-Printing

Some people spend a lot of money on a 3D printer then don't have money for other tools. I did that. I wanted a 1" (25mm) wide belt sander but it wasn't in the budget. Instead of admitting defeat, I decided to make parts for my own belt sander.

Creating the project with only 3D printed parts would have been possible but the filament would have gotten expensive. Instead, I wanted to combine the benefits of inexpensive steel hardware store parts with a printable design. Everything was printed in regular ABS so it's not necessary to track down a rare filament.

http://www.instructables.com/id/Power-Drill-to-Belt-Sander-Conversion/

Podem agora criar Modelos pelo Sketchup, na Tablet, onde quizerem, encontrar os Modelos que quizerem e guardar o trabalho, tudo na Net, é uma maravilha:

What is my.SketchUp?

my.SketchUp is the core SketchUp modeler, tuned to work in modern web browsers. Draw, orbit, push-pull: make anything you can imagine in SketchUp, anytime you imagine it.Find a 3D model of anything3D Warehouse lives on the web, and now so does SketchUp. Go ahead, find a 3D model of anything while you're working in my.SketchUp.Connect with your models anywheremy.SketchUp uses Trimble Connect to store models online, so they're handy whenever you need them. Create a Trimble account, and get started with 10 gigabytes of free personal storage.

http://www.sketchup.com/products/my-sketchup

Eis uma lista de 100 Projectos Arduino, qual deles o mais bacano, cortesia da Autodesk Circuits com de tudo um pouco de introducção ao GPS, a um lançador de Bolas de Golfe, dos quais, destaco este, obra do nosso amigo Algarvio, de origem Francesa, o Alex Negrier, uma versátil Máquina CNC, que tanto pode Imprimir em 3D, como Fresar:

Arduino Controlled CNC / 3D Printer Hybridaldricnegrier in cnc

Mother Nature Makes ... We Build.BuildersBot Fuses 3D Printing & CNC Milling Into One Builder’s Dream "3dprintingindustry.com"The BuilderBot is an Open Design machine, that uses OpenSoftware and Open Hardware. It is a product of open projects such as the RepRap, Arduino and Repetier .The objective of this instructable is to guide your way throw the entire making process of building a BuildersBot machine. An open design Arduino Controlled CNC Router that can also perform 3D printing.The instructions will cover all areas such as design, mechanics, electronics and software.

Para as tais Fresas CNC, acima mencionadas, podem aqui fazer este Acessório, um Mini-Torno, que vos prende o bloco de Material a ser trabalhado, e em 15 Minnutos, está feito!

É bom, e vem com um outro Link, para outro Projecto, onde figurava esta peça:

Mini Vise in MinutesChipsWoodShop in tools

This simple tool is very handy for holding small parts for cutting on the CNC router. I also find it useful for drilling holes and other jobs where I need to hold a small part in place. I made mine from materials I had lying around the garage. I was very easy to make, basically cost me nothing, and was well worth the effort.

This vise was featured in my last instructable on CNC Engraving.

http://www.instructables.com/id/Mini-Vise-in-Minutes

Sem comentários:

Enviar um comentário