Faça o vosso próprio Smartphonne, seja por carolice, seja por estarem faltos de pagar um exagero...

Don't wanna pay trough your nose, for a Smartphone?

Build one!

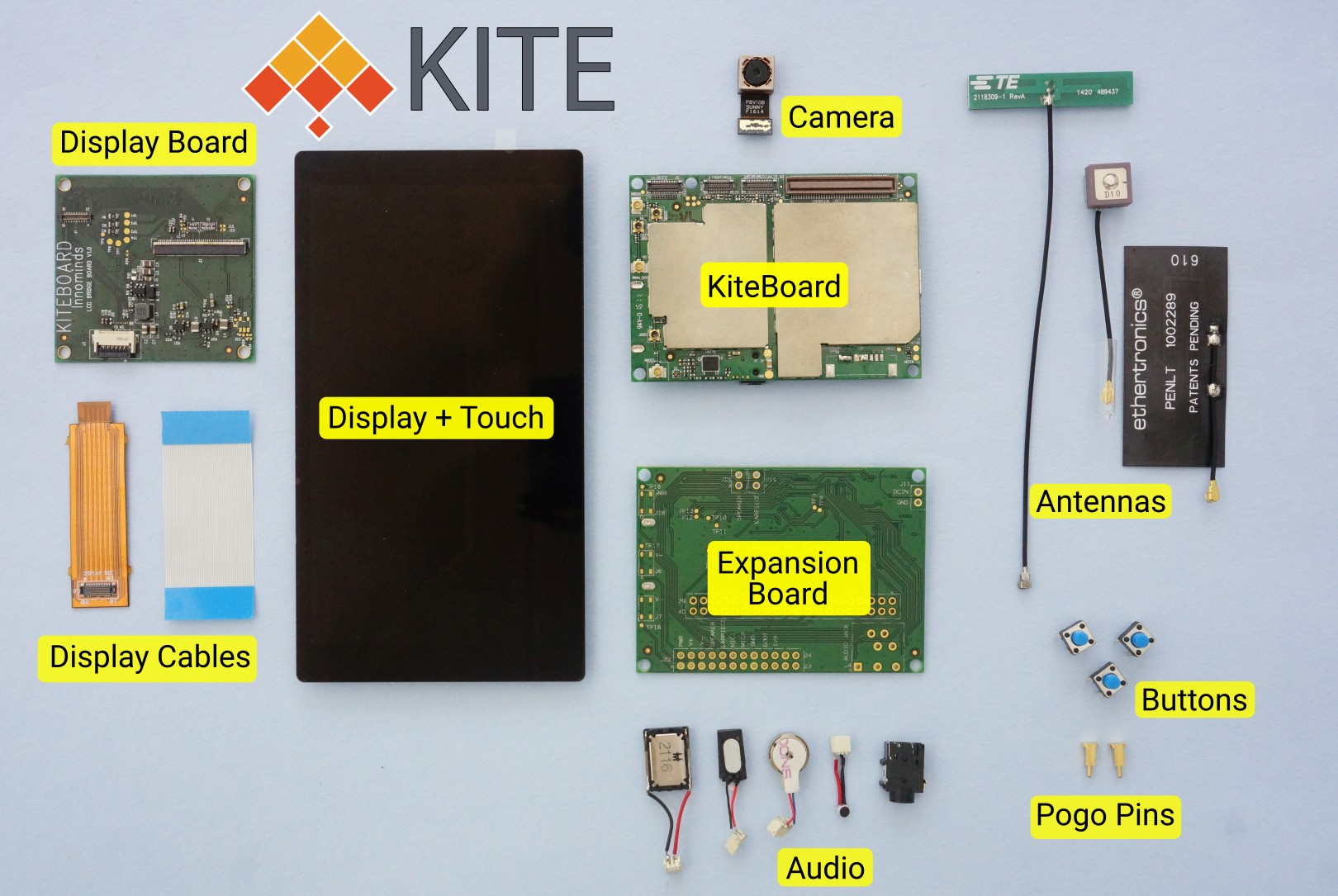

Shree KumarA KitePhone is simply a phone built using the Kite Kit. Consumer phones go through a teardown, so that folks can understand how they are built. Kite is built for makers, so we take a "build" approach here.In this post, I will show you how we’ve put together a minimally complete model of a phone. We call this model, “Poorna”. Poorna is a Sanskrit word, commonly meaning “complete”. It can also mean “zero”, and there are philosophical interpretations too, but then I digress. Poorna is a complete phone providing functionality like the smartphone in your pocket. No additional bells & whistles, just pure Android.Here is a short overview video (exactly 2 minutes, 17 seconds) of how to build Poorna, starting from Kite:

http://www.kiteboard.io/blog/building-poorna-your-first-kitephone

Uma Roda de Genebra, não há quem não acabe por querer fazer uma...

Portanto, aprendam como desenhar uma, como a quizerem!

You'll end up by wanting to make some kind of Geneva Wheel, soo...

Design your own, as you want it.

Make Geneva Wheels of Any Size in a Easier Way

iGreeny

It's not so hard to find the formulas and diagrams if you want to design a Geneva wheel of your own, and you can do it following this article: Make Geneva wheels of any size and this video.

but I feel it's not very friendly to non-engineer readers - at least it took me quite a while to pull out the math and geometry I've learned back in high school. So i decided to translate the formulas into plain English and clearer steps. I also made 2 videos simply recording how I designed it in Fusion 360.

Variables you can decide freely (within a reasonable range)

You and use any CAD software you feel comfortable with because we only need basic sketch functions for designing.

- the quantity of the slots on the Geneva wheel;

- the radius of the drive pin;

- the Geneva wheel radius;

- drive pin clearance.

https://www.instructables.com/id/Make-Geneva-Wheels-of-Any-Size-in-a-Easier-Way/

Sem Soldadura, ficam muito diminuídos, quanto a fazerem engenhocas em Metal, por isso, aprendam, neste Curso, só para vós:

Without Welding, there's no real Metal-made gizmo building hability.

So, get to learn, on a Welding Class, just for you:

WELDING CLASSaudreyobscuraMetal has been worked by humans for thousands of years. Over time, the techniques and technology used to produce and shape metal goods have been driven by the innovations of science and technology.

Before we dive into some of the technical processes available for welding metal together, let's first take a moment to define a weld. A weld is a fabrication process that joins materials, usually metals or thermoplastics, by fusion. Fusing materials is distinctly different than other kinds of lower temperature metal-joining techniques such as soldering, which do not melt the base metal.

Metal welding is the fusing of two pieces of metal to create one solid continuous piece. All welders work on the same principle: A gas torch or electric welder is used to generate precisely directed heat to melt material, and a filler material is introduced by the operator to complete the fusion.

As these processes became more accessible, we've come so far that you - yes YOU! - can learn how to weld easily.

Um Molde para um Molde! Estou farto de dizer isto, a Impressão 3D foi feita para Moldes!

Por isso, vejam como se faz, para poderem fabricar algo em números de jeito:

3D Printing a Mold for a Mold! I keep telling you, 3D printing was made for Molds!

Watch how it's made, so you can produce anything in decent numbers:

3D Printing a Mold for a Mold

Charlotte_J

I have always loved the 3D model of the 'Vaas met oor' (Cup with ear) by Joris Van Tubergen. A couple of years ago I did my first attempt to make ceramic cups of the model. I succeeded and love drinking my coffee from these cups.

Recently I wanted to make some more of them. Only thing: I did not like the handwork that was needed to create the mold.

Inspired by the option 'Mold' in the software for my Ultimaker 3D printer (Cura) I started to think about printing a mold for a mold.

This Instructable shows what I did to print a mold for a mold and how I was able to use it.

https://www.instructables.com/id/3D-Printing-a-Mold-for-a-Mold/

ESTE, parece que não é um Motor Lingrinhas, comparado com os de Explosão...

Quase 4 vezes mais Torque do que o melhor já feito, até agora!

Leiam.

Seems Electric Motors are leaving the Wimpy League...

Have a read, a new Motor, almost 4 times more torque than the best there was, so far!

Magnax prepares to manufacture radically high-powered, compact axial flux electric motorLoz BlainAfter nearly a decade in development, Belgian startup Magnax claims it has developed an ultra-high power, lightweight, compact axial flux electric motor with performance figures that blow away everything in the conventional radial flux world. Crucially, it says it's worked out how to manufacture them too.It might not have the romance of combustion engine tuning, but it seems a bit of a battle is brewing to develop the kinds of high-performance motors that will power the electric cars, motorcycles, aircraft and industrial equipment of the future.

A week ago we wrote about Equipmake's spoke motor design, which allows it to pump out some 9 kilowatts per kilogram with exceptional cooling and continuous power production ability.

To put that kind of power production in perspective, the ludicrously fast 193-horsepower BMW S1000RR superbike of 2011 – a power-to-weight beast that would slay just about anything in the automotive world – has a lightweight motor that makes a puny 2.4 kilowatts per kilogram. So 9 kW/kg is no joke.

Sem comentários:

Enviar um comentário