A Impressão 3D demora muito tempo!

Mas os Moldes para Injecção de Plástico, permitem-vos produzir não uma ou duas, mas centenas de peças.

O que vos resolve uma data de chatiçes...

E vos dá muito mais DINHEIRO!

10 CAD Tricks for Mold DesignMichael LaFlecheMold design is one of the most complex aspects of product design. Not only are the part geometries challenging, but the timeline to get jobs quoted and manufactured are tight. OEM design companies sending designs to contract mold designers is typically the last stage of the design cycle, and “tooling up” can be some of the most expensive parts of the project.

Luckily, there are some mistakes that part designers and mold makers can avoid to reduce time and cost.

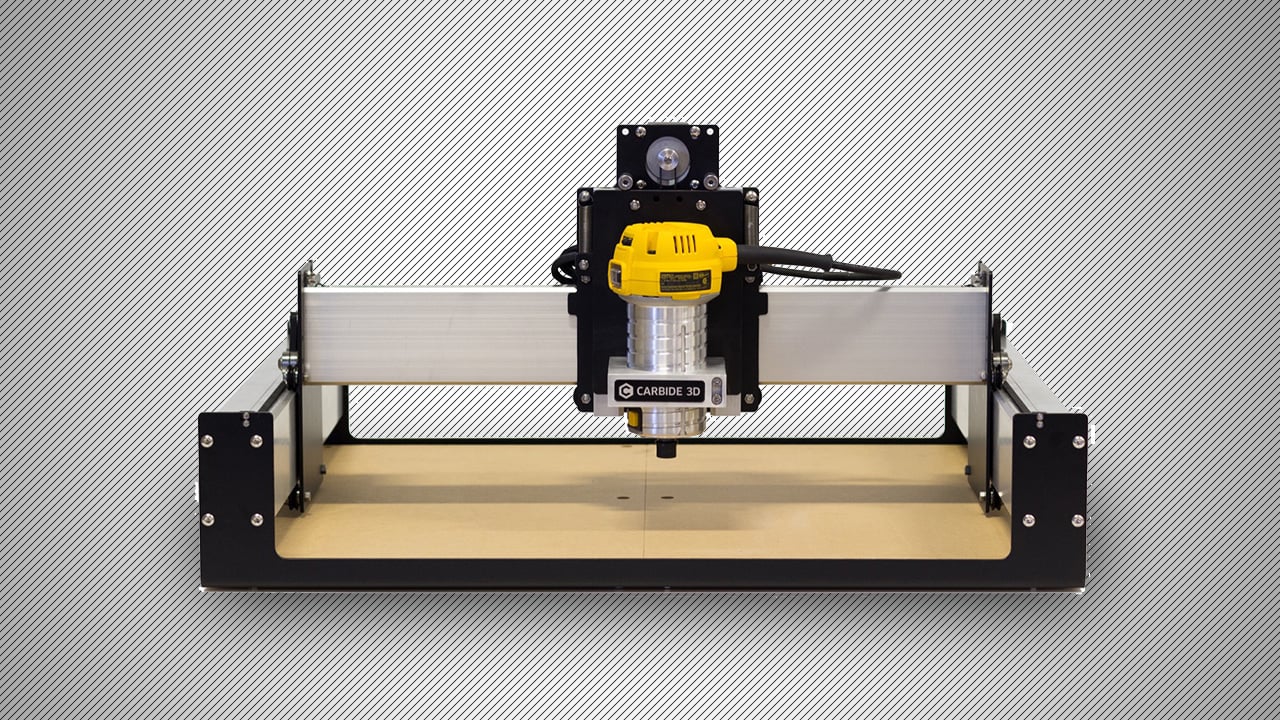

Eis a ùltima Fresa CNC Shapeoko, e vem carregada de novidades, para uma máquina que já era uma maravilha, como estava:

2019 Shapeoko 3 (XXL) CNC Kit Review – Editor’s Choice

Tyler Koslow

Arguably the most popular “desktop-sized” CNC router of the day, the Shapeoko 3 from Carbide 3D has origins waaay back in 2011, when its creator Edward Ford launched Project ShapeOko on Kickstarter.

A sub-$300 open-source CNC machine kit, Project ShapeOko was an affordable entry point into the world of CNC carving, achieving the fantastic feat of simplifying the procurement of parts for an open source project.

With a build comprised of electronics, plus other sundry items such as laser cut plywood sourceable from Shapeways and Ponoko (hence, ShapeOko) and one other provider, Ford’s original machine was a trailblazer.

Fast forward seven years, and much has changed. In 2014 Ford joined forces with CNC machine and CAD/CAM software company Carbide 3D, becoming a partner and VP.

https://all3dp.com/1/shapeoko-3-xxl-review-specs-carbide-3d/

...Mas esta máquina é impressionante, Impressora, Fresa, e Laser CNC, basta mudar as cabeças.

E fazem-na em casa!

Modular DIY CNC V2jtaggardI build my first CNC about a year ago and learned a lot from the process. As an engineer I'm always looking at ways to improve things, and my first machine was no exception. The process began with some small changes which quickly turned into the opportunity to overhaul the design even more to better suit my needs (an overview of these changes is detailed in the next step).

Uma Impressora, mas para escrever no chão, algo que suspeito, vai ser muito usado em MakerFaires...

StreetWritercharlesgloriosoI started this project because I wanted to make my mark on the world but didn’t want to leave any aftereffects.

I also wanted a challenging project for my new 3D printer that involved some Arduino Programming.

Finally, I like to build things using as much “found” stuff as possible.

As the videos show, StreetWriter does all of that. It writes 8 inch high messages in water on the pavement as it moves, and leaves no trace once the water evaporates.

I have built two StreetWriters, with minor design differences between them, This Instructable, is based on the second build which is somewhat improved.

In StreetWriter, water is pressurized and fed to a manifold which carries 8 automotive fuel injectors. As StreetWriter moves forward, the Arduino controls the fuel injectors, squirting water onto the pavement. The message to be written is one of 8 that have been written onto an SD Card plugged into the Arduino. The operator can easily select among the messages and can create new messages on the SD card at a computer. There is no length limit on any one message other than the amount of water in the pressure tank. The longest message I have written so far is PI to 300 places.

...E acaba-se, por hoje, com esta 3ª Mão, para não terem uma crise de nervos, nem quemarem os dedos, quando estão sós, na oficina!

Magnetic 3rd Hand

lonesoulsurfer

Anyone who plays arounsd with elecronics knows how important a 3rd hand is. It gives you the ability to hold solder in one hand and the soldering iron in the other and easily add solder to a component.

I've been using some homemade 3rd hands for some time and can't imagine building a circuit without one. Recently I was using a couple of magnets for a project and a resister got stuck to it. I had a bit of an epiphany and realised that adding a magnet to a 3rd hand would be a quick and easy way to hold a part whist I add solder to it.

The project is an easy one and will definitely become a welcome addition to your solder station.

https://www.instructables.com/id/Magnetic-3rd-Hand/

Sem comentários:

Enviar um comentário