O que vos pode safar a vida de muitas chatiçes, é este simpático Mapa de Fornecedores de Filmento , peças, e Impressoras 3D, dos nosso amigos da Reprap.pt

Poupa-vos terem de esperar meses por uma peçita de nada, por encontrarem a Loja mais perto de vocês, que uma Loja física, é outra coisa...

Vão lá:Mapa de onde adquirir uma Impressora 3D, Peças e Filamentos para uma RepRap em Portugal

Mapa de Peças, Filamentos e Impressoras 3D

Não és administrador deste mapa? Pede-nos que enviamos-te o link para alterares e adicionares a tua localização. Este mapa também é para quem tem uma impressora 3D e quer imprimir. Vê como está organizado e adiciona uma nova camada ou adiciona a uma camada já existente.

https://reprap.pt/impressoras-impressao-3d-em-portugal

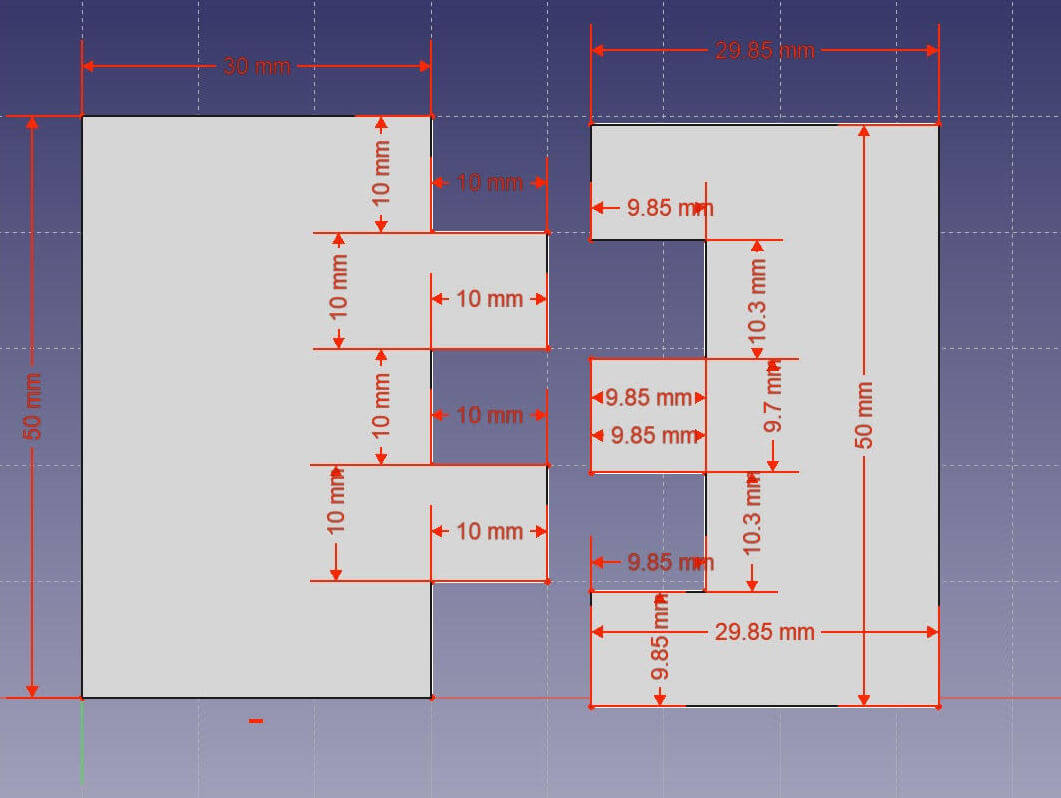

Tantas vezes que se tem de ajustar à bruta, e por tentativas, quando se quer imprimir em 3D, peças que encaixem umas nas outas...

Mais uma dor-de-cabeça!

Mas a scupteo vem-nos ajudar, com este belo deste Tutorial, sobre como ajustar a Impressão para peças que servem, à primeira!

Fantástico.

The ultimate guide to designing 3D printed interlocking parts

Katarzyna Plewa

With 3D printing technologies, the design freedom is just endless. Additive Manufacturing allows for the absolutely new use of design tools, such as interlocking tools. Thanks to 3D printing you are not able to combine different technologies and materials. Discover the benefits of 3D printed interlocking parts now!

In this blog post, we will go over the advantages of 3D printing interlocking parts, we will advise you which 3D technology will the best for different production needs and our 3D printing experts will show you our own study case of designing interlocking parts.

What are the benefits of 3D printing interlocking parts?

First of all, Additive Manufacturing gives you a wide range of materials, providing you with the best choice for your production needs. Every product you design is different, and to give you the best 3D printing experience we offer 18 materials across 8 3D technologies. Surely, one of them will perfectly fit your manufacturing preferences, whether you need your parts to be flexible or heat resistant.

Additive Manufacturing gives you amazing design freedom as the technology is capable of much more than traditional manufacturing methods. Your products can reach a new level of complexity allowing for better solutions for your production needs. Indeed, with 3D printing, you can easily design interlocking parts thanks to the high accuracy of 3D printing.

https://www.sculpteo.com/blog/2018/10/10/the-ultimate-guide-to-designing-3d-printed-interlocking-parts/

A não ser que queiram queimar Motores, e aleijar os dedos, podem muito bem recootrer a este Mini-Curso de 5 Aulas, sobre como montar e controlar as bestas que arranjam nas Sucatteiras e afins, para fazerem aquele Kart eléctrico, ou lá o que seja...

LARGE MOTORS CLASSrandofoIn this class I will show you how to control motors that are suitable for building go-karts, electric scooters, large robots, and much more. This requires a very different set of knowledge and skills than would be necessary for controlling a small hobby motor.

This class is intended for students with some experience working with motors, and mechanical systems. By the end of the class you will learn how to pick the correct power supply, build a control circuit, and adjust the speed of a motor. You will also learn how to make a circuit which reverses the direction the motor is spinning.

Motor control is demonstrated by a range of techniques such as using motor controllers with analog throttles and also with Arduinos and motor controllers.

I hope that you will come join me in the wild world or large motor control.

Um Oscisloscópio de Bolso?

Ainda melhor, do tamanho duma caixinha de Fósforos!

Espantem os Colegas com esta pequena maravilha, que nem preciso de dizer mais nada, bolas, isto é a ambição de qualquer Engenhocas que se preze!

Oscilloscope in a Matchbox - ArduinoPeter BalchWhy would I want a tiny oscillscope? I've got a room full of electronic Stuff including four oscillscopes. But it's a fuss using them. It would be nice to have something that fits in my pocket, that sits next to the circuit I'm working on and that's as easy to use as a multimeter.

This oscilloscope costs the price of an Arduino Nano (£2 and a display (£3) plus a few pence for resistors, etc. It's specification is:

- max 1M samples/second, min 1000sps

- 8-bits per sample

- DC 0-5V; AC +/- 550mV, AC +/- 117mV, AC +/- 25mV

- USB "PC scope" or built-in display

- could be battery-powered

- optional logic display

- optional frequency meter

- optional voltmeter

Conseguem ter uma Impressora 3D em casa, com cerca de 60 Euros, e Material Reciclado!

Sabe-se lá quantos Jovens Génios não se despertará com esta bela Miniatura, que pode imprimir...

Miniaturas!

É que isto é mais un Curso de CNC disfarçado, que outra coisa, com o bánus de se ter algo de bem útil, no fim, e se conheço a Malta Geek, quem faz esta, fará outra bem maior, um dia...

Quem faz um Cesto, faz um Cento!

Intro: EWaste 60$ 3DPrintermikelllcThis project describes the design of a very low budget 3D Printer that is mainly built out of recycled electronic components. The result is a small format printer for less than 100$.

First of all, we learn how a generic CNC system works (by assembling and calibrating bearings, guides and threads) and then teach the machine to respond to g-code instructions. After that, we add a small plastic extruder and give an overview on plastic extrusion calibration, driver power tuning and other few operations that will bring the printer to live. Following this instructions you will get a small footprint 3D Printer that is built with about an 80% of recycled components, which gives it a great potential and helps to reduce the cost significantly.

On one side you get an introduction to machine building and digital fabrication and on the other side you get a small 3D Printer built out of reused electronic parts. This should help us to be more conscious about the big problems related with e-waste generation.

Sem comentários:

Enviar um comentário