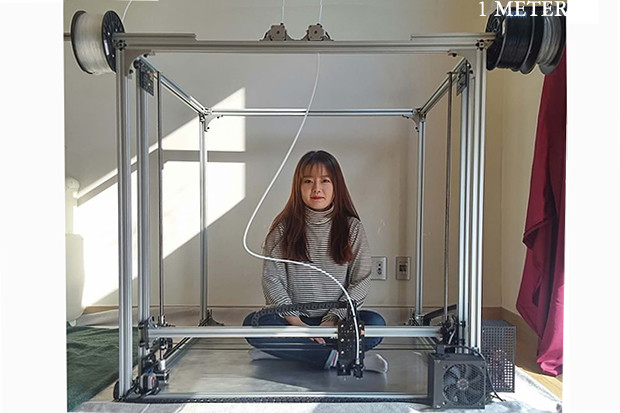

Não é preciso ter de imprimir pecinhas pequeninas, não com esta proposta de Incheon, na Coreia do Sul.

Com preços a partir de 500 Dólares, em Kit...

Eis um Projecto a apoiar.

Want a bigger printer ? You can easily expand our printers. Reasonably priced LARGE print bed.bigger 3D printers

After a year of hardwork. Blood (literally) sweat, and tears. It is time.. We are Colossal3D. ( c3d for short ). And there is only one goal for us. We will make larger 3D printers available at a reasonable price. By larger we mean ½ meter print bed or larger. With our expansion kit, print area can go to 1 1/2 meters, 2 meters or more. No need to buy another printer. Bored with printing something that can fit in a suitcase. You can print the suitcase.How about printing a big Drone that can fly for hours or carry a heavy payload ? Or a custom Kevlar bicycle frame (2 pieces, frame and front forks), a backpack, a toolbox, an insane chair for computer gaming, or a canoe. Not in 12 pieces, in only 1 piece. With multiple extruders, parts can be printed in multiples. With a second controller board it is possible to use 2 independent gantries on the larger printers. A first in the consumer 3D realm.

We offer 3 types of printer. Desktop. $2000. 1 Cubic meter $2,500, and 2 Cubic meter with plexiglass enclosure. Price on request.UPDATE !! We offer D I Y kits for $500 lower price.

Dica de Rodrigo Vertulo, no Blogue Laboratótio de Electrónica, aprendam, com as necessárias equações, como reduzir a velocidade, aumentando a potência...

Ou ao contrário, se invertermos a ordem das rodas dentadas:

Redutores; nem sempre mais rápido é melhor!Rodrigo VertuloO uso de motores na automação de processos industriais é uma realidade incontestável e a presença dos diversos modelos de motores é facilmente notada nos variados tipos de máquinas que “populam” os parques industriais, sendo, inclusive, intensamente utilizados nos robôs industriais como principal elemento de movimentação desses equipamentos.Os motores em geral possuem duas características muito importantes que devem ser levadas em consideração ao serem utilizados, ou seja, a velocidade de rotação e o torque. A velocidade de rotação determina quantas voltas por minuto o eixo do motor é capaz de executar e normalmente é chamada de RPM (rotações por minuto). Por outro lado, o torque é a força que aparece no eixo do motor quando ele gira e depende da distância entre o ponto em que uma carga é aplicada ao eixo até o centro do mesmo. Em outras palavras, quanto maior for o torque do motor maior é a sua capacidade de movimentar cargas mais pesadas.

Querem moldar algo em grande?

Usem a Fita auto-colante da grossa, tipo Duct Tape, para fazer o que quizerem, como por exemplo, Armaduras, Vestuário, ou toda a espécie de Engenhocas, como Bicicletas, Drones, Próteses, etc.

Cast or Pattern Anything with Duct tapeashleyjlongIn this Ible I'll be showing you how to use regular ol' duct tape to duplicate an existing object, then create a 2-dimensional pattern from the duct tape duplicate. This may not be one of my more attractive Ibles, but the methods explained herein have infinite applications if you're a prop builder, costumer, or puppet maker. In fact, the woman who taught me this method worked for the Henson Co. for many years and said this was how they'd get patterns for "skinning" puppets after the forms had been carved out of foam.This is a very budget friendly method for the following problems:--I want to make a corset/costume, but I don't have a dress form. Just to give you an idea of the potential here, I've included a photo of a duct tape full body cast my friend, artist Deb Winslow, made in order to fit armor for a masquerade ball we attend.--I want to re-upholster this prop, but I don't want to massacre the original to get a pattern.--I have a cool object I want to duplicate, but I don't have the skills/ materials/ workspace to do casting and molding. Mold making putty works fine for small objects, as in my Glitter Grenade Soap Ible, but larger objects may be best served by this duct tape treatment.

Para ligarem mais não sei o quê, por Bluetooth, eis um Instructable para o fazerem, e por um preço bem em conta...

3 Dólares!

$3 Bluetooth HID Module (HC05 With RN42 Firmware)EvanKaleBluetooth HID (human interface device) modules will let you create bluetooth peripherals that can pair with mobile devices out-of-the-box (like bluetooth keyboards, gamepads, mice, etc.).If we're looking to build our own bluetooth HID device, the hefty price of a single HID module can spike the budget of a project (like the BlueSMiRF HID for $40 USD, or the BlueFruit EZ-KEY HID for $20 USD).An inexpensive bluetooth serial module commonly used by hobbyists, the HC-05, sells for $3 USD, but is not HID capable by default. With a bit of a firmware hack though, we can turn this cheaper module into a bluetooth HID module.

E por falar em, barato, eis mais uma Impressora 3D para combater a Crise, uma versão aproximada da Ultimaker, mas por quase um terço do preço a Ultifaker!

UltiFaker²Go 3D PrinterPaulSS

I set out to make a 3D printer about 3 months ago. I had been eyeballing designs like the Prusa i3 or a delta style printer but I wanted something a little bit more sturdy, less "hack job" looking, and a printer challenging enough to make it interesting. I decided to go with a "clone" of the Ultimaker²Go mostly because it's small enough that the side panels could be machined in my CNC router.I also didn't want to do a direct clone. The Ultimaker²Go sells for a whopping $1600 and I wanted to keep the price around $500-$600. I decided to heavily tweak the design and components in order to drop that cost. This build requires that you have some sort of CNC router capability unfortunately unless you want to use 6mm birch plywood as the paneling (totally doable) and drill and cut the panels by hand.

Sem comentários:

Enviar um comentário