Isto é uma maravilha!

Não só podem construír uma Impressora 3D, a partir de Sucata Electrónica, como, ainda por cima, aquela que vocês puderem arranjar!

À medida das vossas possibilidades!

A partir dum programa que descarregam, Retr3d, e do FreeCad, ambos grátis, é calculada uma Impressora que vai usar o que apanharam, para poderem ter 3D por quase nada...

Impecável.

Retr3D Building 3D Printers from e-wasteHow Does it Work?NOTE: The Retr3D printer has been redesigned and now is as shown above. Designs for V2.1 can be found here. For build instructions see the file named "Build Documentation Master.pdf" in the Documentation folder. If you need help preparing V2.1 STL files for your printer please send an enquiry to enquiries@techfortrade.org.Retr3d is a framework dedicated to affordable 3D printing equipment for developing economies that can be locally sourced, locally maintained and locally improved.We believe that 3D printing can be as transformative in developing countries as the mobile phone. As with the mobile phone, which has already changed the way people across the Africa communicate, introducing 3D printing at the community level offers the potential to localize manufacturing. Which is why we are making it possible to build Retr3d machines from the thousands of tonnes of e-waste which would otherwise end up as landfill.

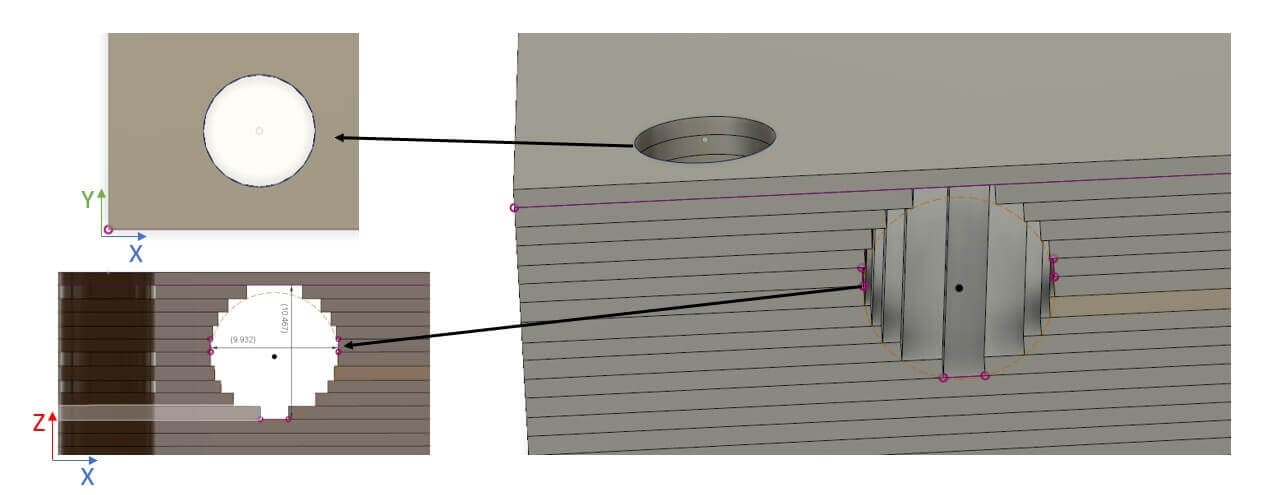

Retr3d creates 3D printer designs based on the materials that you have access to. Retr3d can create printers form mismatch parts gathered from e-waste. All you need to do input the important the important dimensions of what you are using and Retr3d will handle all of the design changes required to make a functional printer. The designs are created using a series of Python scripts that are run in FreeCAD. When the design is finished, a folder is created with all of the design files and STL files needed to build the printer. With Plater and Slic3r integration, Retr3d can even arrange and slice the STL files for you.

Getting Started

Read the safety documentation.

Download and install Retr3d and FreeCAD.

Download and read the note: "E-Waste Components" from the files tab.

Download the "Retr3D BOM" from the files tab and gather your materials.

Follow the "Retr3D instructions" from the files tab to design and build your printer.

E é também à medida, que podem fazer Máquinas-Ferramenta, como esta, que soa mais próxima das Indústrias Portuguesas.

Para que nâo tenham a ideia de que a Vention é só para Impressoras 3D, vejam aqui uma Cortadora de Tecido, idealizada na Net, por quem precisou dela, e pronta a ser-lhe mandada, às peças.

Um trunfo para Empresas e Indústrias Nascentes...

Fabric Cutting MachineStephen GalleDESCRIPTION:

Machine to cut fabric at different lengths, max. 3m. A pneumatic gripper on gantries, driven by 2X timing belt actuators, grasps the fabric on one end of the table. It pulls the fabric all the way to the other end, in sync with feeding rollers. When the required length is reached, clamps hold the fabric in place and another timing belt actuator allows for a circular blade to cut.

O que se imagina, e o que acaba por saír da Impressora 3D, raramente coincidem, à primeira, por isso, para evitar dores-de-cabeça, eis este belo Artigo, da Sculpteo, sobre como orientar as vossas peças, de forma a terem os melhores resultados:

How does part orientation affect your 3D printed parts?Katarzyna PlewaIn all the traditional manufacturing processes, orientation is a parameter which has an impact on the feasibility of the part. A bad orientation choice will make the part complicated to produce, and will raise the cost of the final part. With machining, you try to minimize machining time, and thus, to minimize the number of operations and positions. With casting, you try to find the most simple mold. In all cases, the technology and the orientation of manufacturing are parameters that need to be taken into account as soon as part conception begins.Some additive manufacturing processes are not impacted by orientation when it comes to the feasibility of the part, that’s mainly the case for powder-based technologies such as SLS or HP Multijet Fusion. With these technologies, part orientation mainly has an impact on the quality of the final part.

https://www.sculpteo.com/blog/2018/08/29/how-does-part-orientation-affect-your-3d-printed-parts/

Quando quizerem fazer uma Impressora mesmo grande, não se fiquem pelos 12 Volts das pequenas, vão até aos 24 Volts, e uma placa aquecida, a funcionar a 110 V!

E está aqui abaixo, como o fazer.

Upgrading 3D Printer From 12 to 24 Volt

Core3D

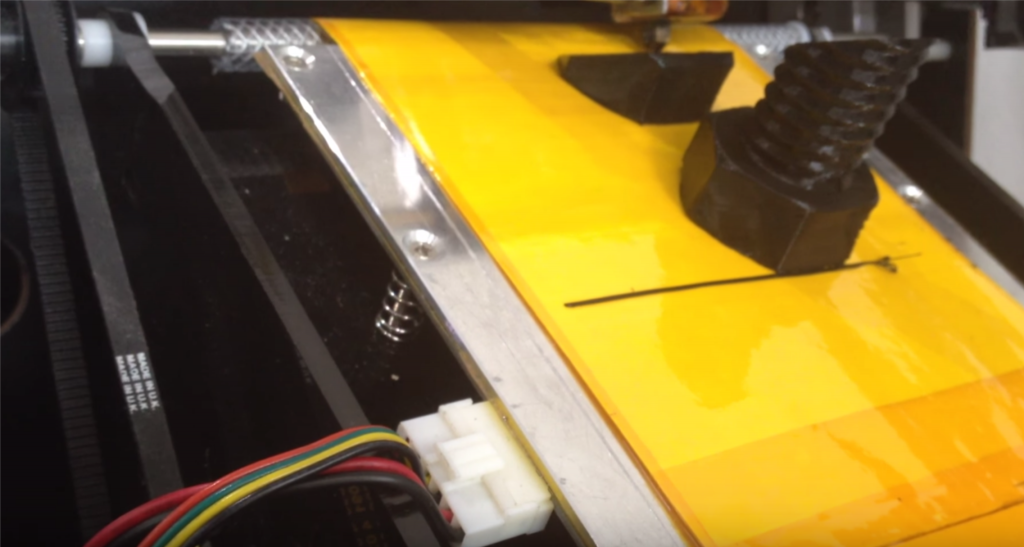

My CoreXY is a beast. It has 4 2A stepper motors, 4 TMC2130 stepper drivers, 110 Volt heated bed, enclosed case and for almost 3 years now has been running on a 12 Volt knock off RAMPS 1.4. It's like a corvette running on a corolla engine.

There is anecdotal information about things heating up faster (which I'm not convinced of as you will change the heater cartridge) but most importantly, I've read that TMC2130 Stepper drivers operate better on 24 Volt and stepper motors have more torque when upping the voltage.

If anything, as you can see from the images above, upgrading to 24 volt certainly has made me revisit my wiring. That alone brings a feeling of immense satisfaction.

In this instructable I will discuss the 24 volt upgrade of my printer which is a CoreXY with 2 2A steppers, 2 1.7A steppers, Direct extrusion, parts cooling fan, controller cooling fan and LEDs.

In my upgrade I'm using a KFB2.0 controller board but there are many other alternative boards that can handle 24 Volt. The RAMPS 1.4 happens to be one that is not built to handle 24 Volt (there are upgrade options to that).

Many of the items will be similar in your printer and might be handled the same.

https://www.instructables.com/id/Upgrading-3D-Printer-From-12-Volt-to-24-Volt/

Se se imprimir sobre uma correia podem-se produzir Impressões teóricamente sem-fim!

Ou até acabar o Filamento...

Mas, a sério, esta é uma Inovação importante, porque com isto, até pranchas de Surf se podem imprimir, de uma levada.

Brutal:

New conveyor belt 3D printers Polar3D Flash and Printrbot PrintrbeltMichael Petch3D printing with conveyor belts has seen a flurry of activity this year. Now, Bill Steele of Polar3D has posted several interesting videos featuring new 3D printers.The Polar3D Flash FDM printer uses a conveyor tilted at an angle to produce a continuous stream of parts. In the video the print head moves in the X and Y axis, as in any cartesian FDM machine, however the Z axis is a conveyor belt – angled at 45°.Another video posted this week shows a 3D printer Steele calls the Printrbot Printrbelt. This machine is the result of a partnership between Polar 3D and Printrbot.Brook Drumm from Printrbot demonstrated the Printrbelt ahead of sending it down to the machines first public demonstration at the International Society for Technology in Education (ISTE) event in Texas earlier this week.The Printrbelt’s printhead moves on an X axis angled at 35° to the Z axis composed of a heated print bed conveyor belt. Drumm got in touch to tell use, “It’s out of beta and for sale for early adopters who want to get on that bleeding edge.”The Printrbelt also features automatic part ejection.

Sem comentários:

Enviar um comentário